- Aquatic feed pellet die

- 1.0-2.2mm

- 18-30

- 11-26%

- 400-1000hours

Products Description

Aquatic feed pellet die is the core component of the fish and shrimp pellet die pellet machine. It converts powdered raw materials into pellet feed suitable for aquatic animals through extrusion molding technology. Its application involves multiple technical links and industry needs. Aquatic feed pellet die is specially designed for aquatic animals such as fish and shrimp. It can produce sinking, floating or slow-sinking feed to meet the feeding habits of different aquatic animals.

Product Parameters

|

Material |

Hardness |

Hole Diameter |

Hole Surface Roughness |

Hole Size Error |

|

X46Cr13 |

52-55 |

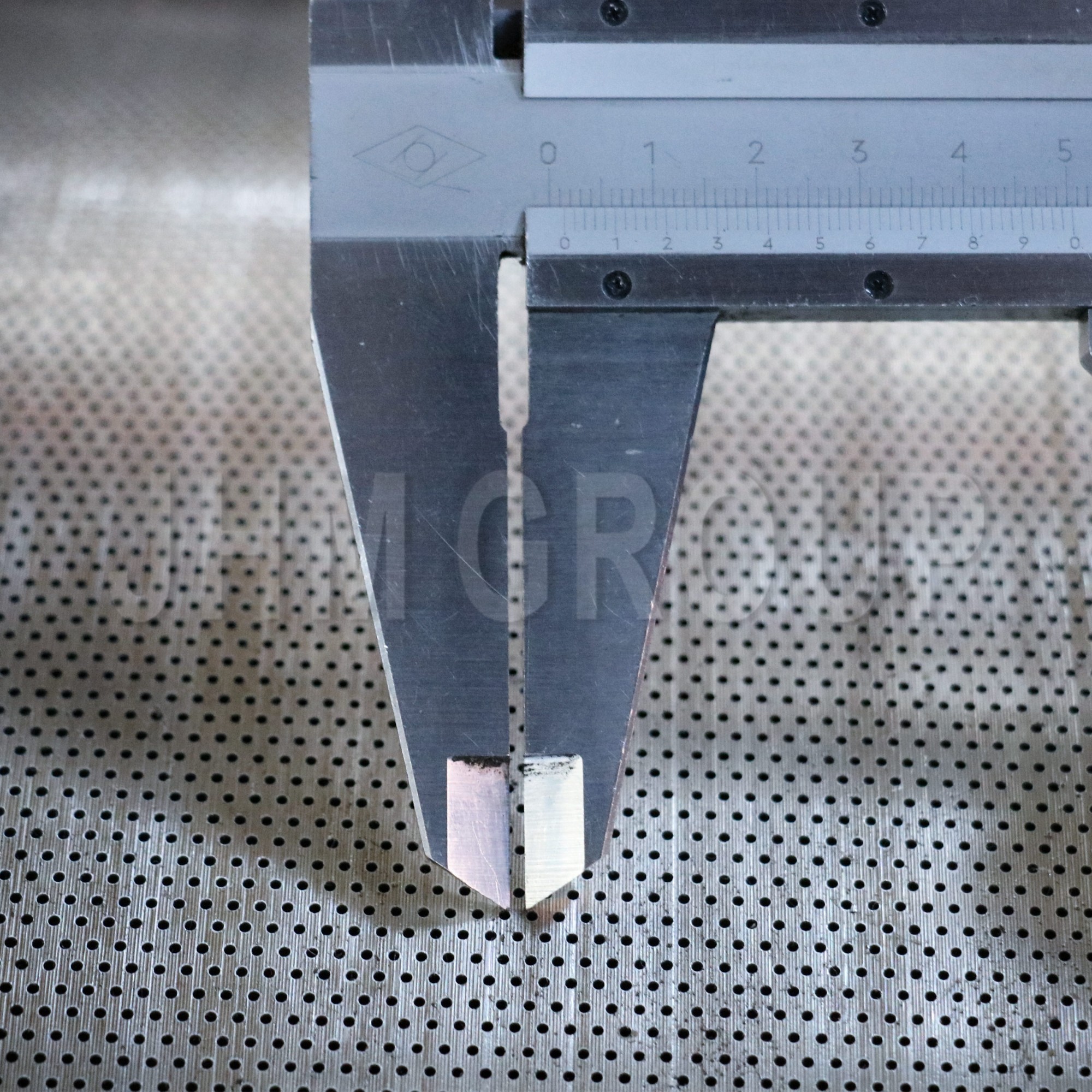

1.0-30mm |

0.4-0.8μm |

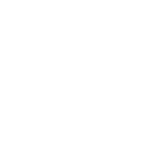

±0.04mm |

|

20CrMnTi |

58-62 |

3.0-30mm |

1.6-3.2μm |

±0.04mm |

Remark: Opening rate of pellet die depends on the thickness and application finally.lf the die is not thick enough, opening rate shall be decreased appropriately to avoid crack.

Product Features

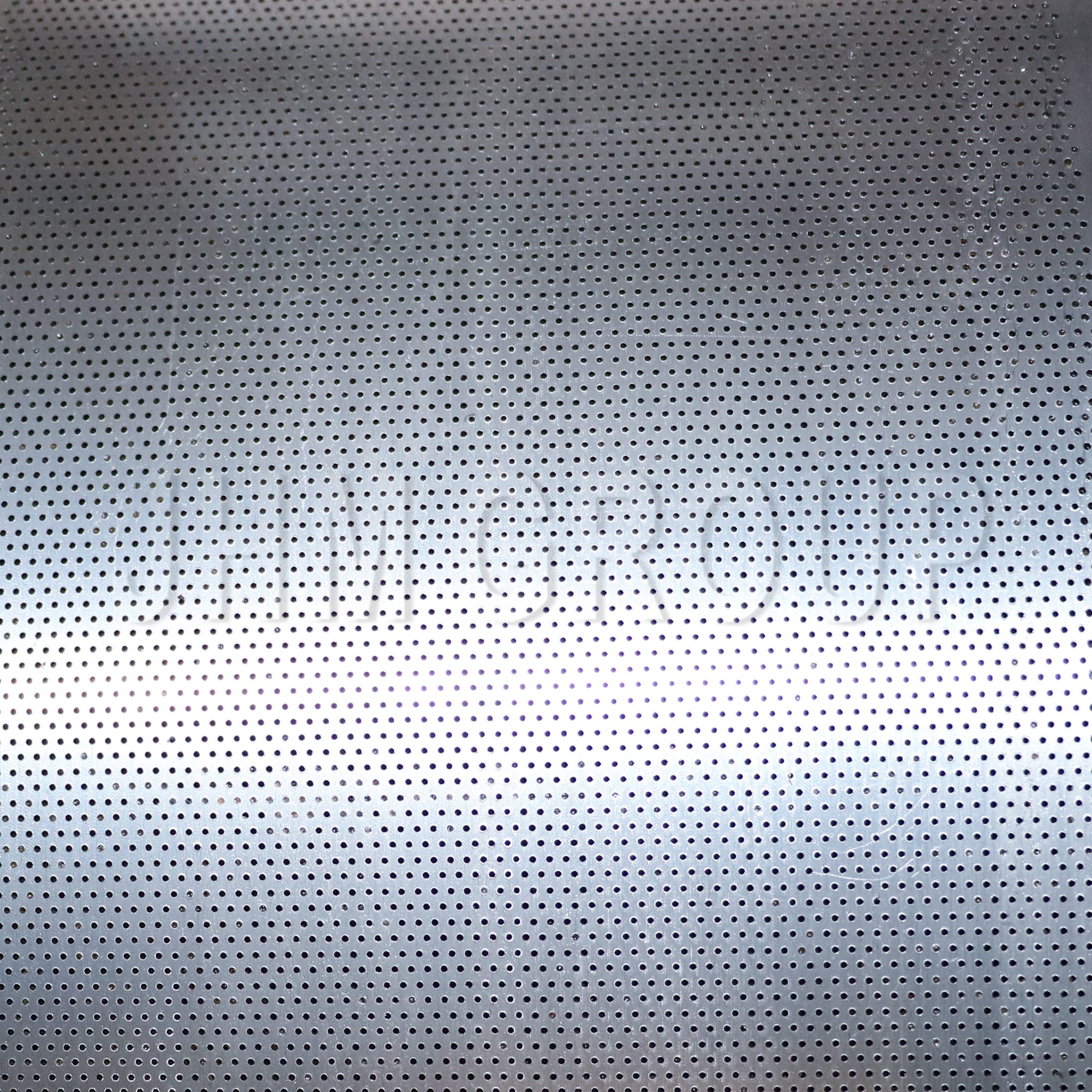

·Material: X46Cr13

·Stainless steel or high wear-resistant alloy steel is used to adapt to the high oil and high corrosion characteristics of aquatic raw materials.

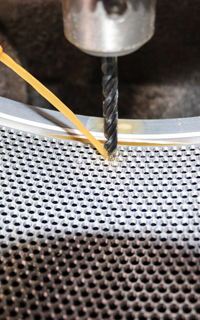

·CNC deep hole drilling + vacuum heat treatment ensures that the die holes of the aquatic feed ring die are smooth, the material discharge is smooth, and the holes are not easily blocked.

·The mold has high hardness, small deformation and stable hole shape, which greatly extends the service life and reduces the overall cost.

·Service Time: 400-1000Hours

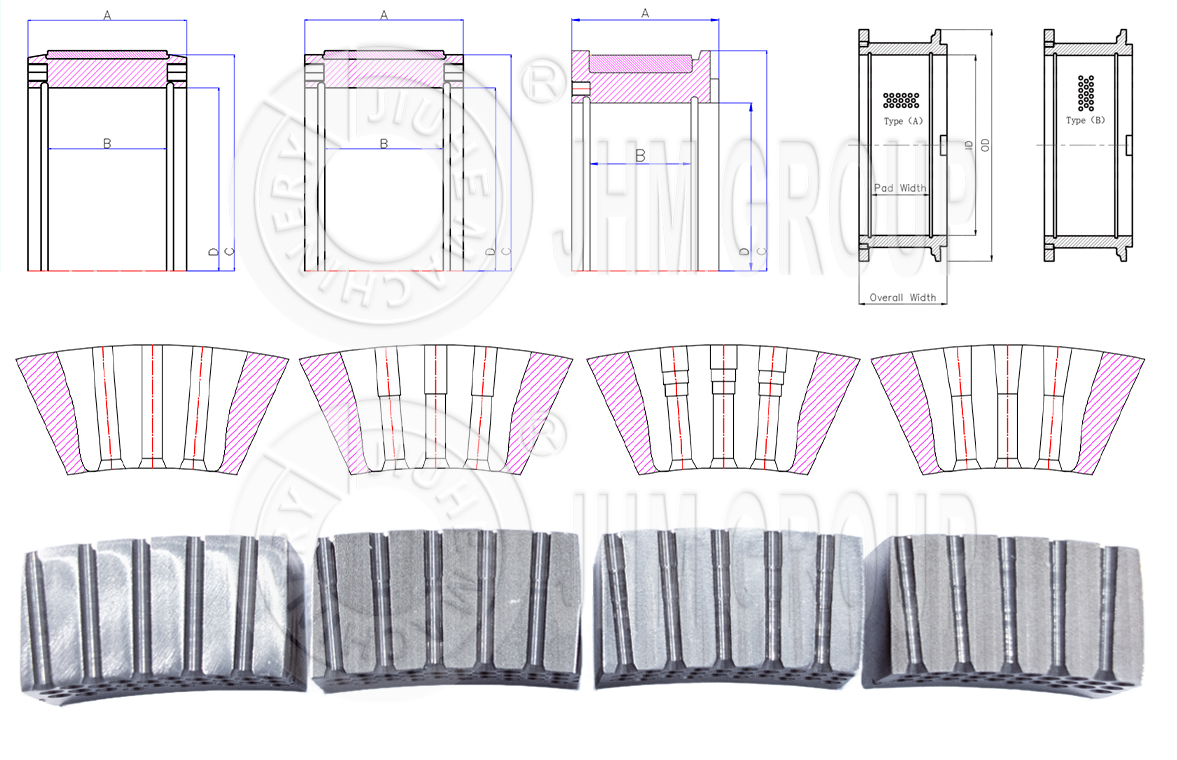

Our die is characterized by its special distribution of holes. The relative position and pattern of our die holes improve optimum capacity of the pellet mill. The unique hole distribution of the die ensures:

1. Longer life (even wear)

2. Higher capacity with the same Die open area

3. Lower power consumption per ton of produced product

Pellet Die Type

JIUHE MACHINERY can customize the out shape and hole shape of the pellet die according to pellet type, raw material, customer demand and application. Mould shape: screw type with bevel edge,screw type with straight edge,clamp type.Hole shape: straight hole,straight hole with single relief,straight hole with multi relief,straight hole with conical relief.

Production Process

Metal Forming

Metal Forming

Lathed

Lathed

Ultrasonic testing

Ultrasonic testing

hole drilling

hole drilling

Automatic chamfering

Automatic chamfering

Vacuum quench

Vacuum quench

Inspection and Measurement

Our expert team is available to guide you by selecting the right die. In addition, we have service agency in different countries, such as Russia, Iran, Egypt, Bangladesh, India, etc,which can help solve all kinds of problems you face in time.Our engineer will also visit our client annually.

Production Application

Applicable fields Formulated feed for white shrimp Pellets for tilapia, sea bass, and eel Sinking feed for marine fish, slow-sinking pellets Micro-particle feed for aquatic seedlings;Choose the appropriate aperture according to the mouth size of the fish or shrimp. Usually 0.8-1.5mm is used for young fish and 2mm for adult fish;According to the particle density requirements and formula characteristics, the compression ratio and pore size distribution are accurately customized to improve the molding rate.

Tips

The aquatic feed pellet die achieves efficient conversion from raw materials to high-quality pellets through precise design and intelligent regulation.

Customized ring die design: For special aquatic products (such as salmon and grouper), special-shaped ring die can be developed in the future to improve the palatability of feed.

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger