08-18/2025

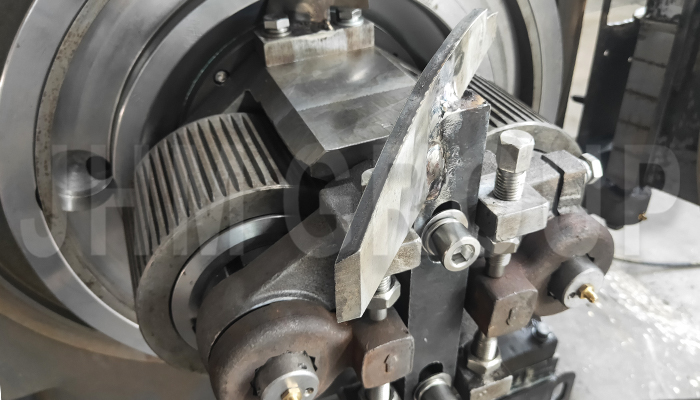

During pellet production, a customer discovered that the pellet mill's roller stopped rotating and became overheated. After inspection by after-sales engineers, they discovered that the cause was damage to the pellet mill's roller bearing. Many people are unclear about when the roller shell broke down, and what exactly causes the roller bearing to break down.

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger