OUR SERVICE

JIUHE specializes in pellet machines and key components, serving the feed, biomass, and chemical industries. With excellent craftsmanship and quality, we lead technological innovation and enjoy strong trust from customers worldwide. Committed to strict quality control and professional service,We helps clients improve production efficiency and competitiveness.

According to systematic research and technical communication, such as raw material types and physical properties, pellet specifications, production capacity and operating conditions, as well as special working conditions, we could realize the customer’s actual application requirements comprehensively and thoroughly.

JIUHE MACHINERY aims to provide a scientific and precise technical basis for pellet mill selection, ring die parameter design, and overall process configuration, ensuring efficient and stable equipment operation.

Through a thorough understanding of application scenarios and raw material characteristics, our engineering team delivers tailored solutions based on specific customer requirements. The services include equipment model selection, system configuration, design adaptations for challenging material, ring die parameters optimization, and heat-treated surface hardness.

JIUHE MACHINERY aims to provide a scientific and precise technical basis for pellet mill selection, ring die parameter design, and overall process configuration, ensuring efficient and stable equipment operation.

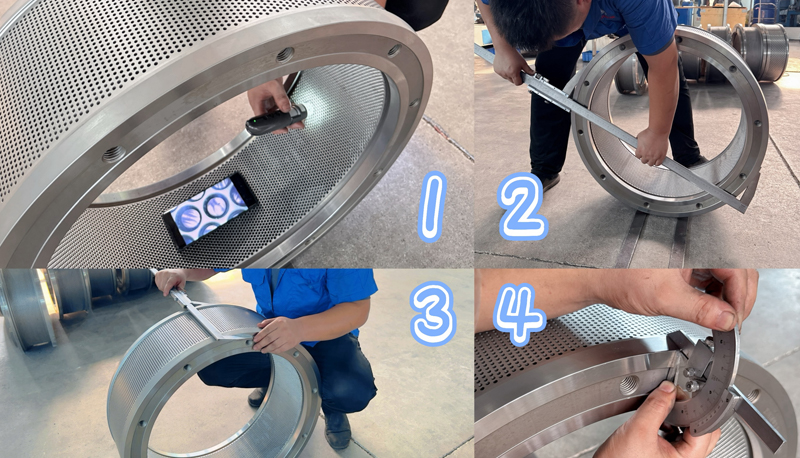

The pelletizing equipment is processed in full compliance with ISO quality standards. Key components are made from high-strength alloy steel and processed with precision machining, heat treatment, and dynamic balancing to ensure durability and smooth operation. Pellet die is crafted from wear-resistant stainless steel (X46Cr13) and finished with deep-hole drilling, and vacuum heat treatment for consistent accuracy, strength, and corrosion resistance.

JIUHE MACHIENRY aims to delivering high-efficiency, stable, and long-lasting solutions for modern pellet production.

A comprehensive factory quality inspection system is implemented strictly to ensure high performance and reliability of our equipment. The equipment undergoes mechanical precision, electrical safety, and load testing for smooth operation, while ring dies undergo dimensional and hardness checks for durability. Each unit is delivered with a detailed factory inspection report, ensuring the products meet industrial-grade continuous high-load production requirements.

JIUHE MACHINERY aims to provide customers with stable, efficient, and durable pelletizing solutions.

JIUHE MACHINERY offers comprehensive installation and commissioning online support, such as guidance on calibrating the gap between rollers and ring dies, installation orientation and precautions, initial startup parameter recommendations, and break-in operation guidance. Additionally, based on actual process requirements, we offer process optimization solutions such as speed adjustment and feed rate balancing.

JIUHE MACHINERY aims to shorten the commissioning period, ensure safe equipment startup, and achieve rapid, stable, together with efficient pelletizing operation.

JIUHE MACHIENRY provides comprehensive after-sales and technical support services, such as fault diagnosis and remote technical assistance, prompt supply of original spare parts, as well as ongoing production optimization advice, wear analysis, and preventive measures. Additionally, we address technical issues like clogging, cracking, and abnormal wear by providing lifespan evaluations, and parameter optimization support.

JIUHE MACHINERY aims to extend equipment service life, enhance overall pelletizing efficiency, and help customers continuously reduce costs and improve profitability.

GLOBAL SERVICE

24/7 Response

Delivering Unmatched Service Excellence Anytime, Anywhere

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger