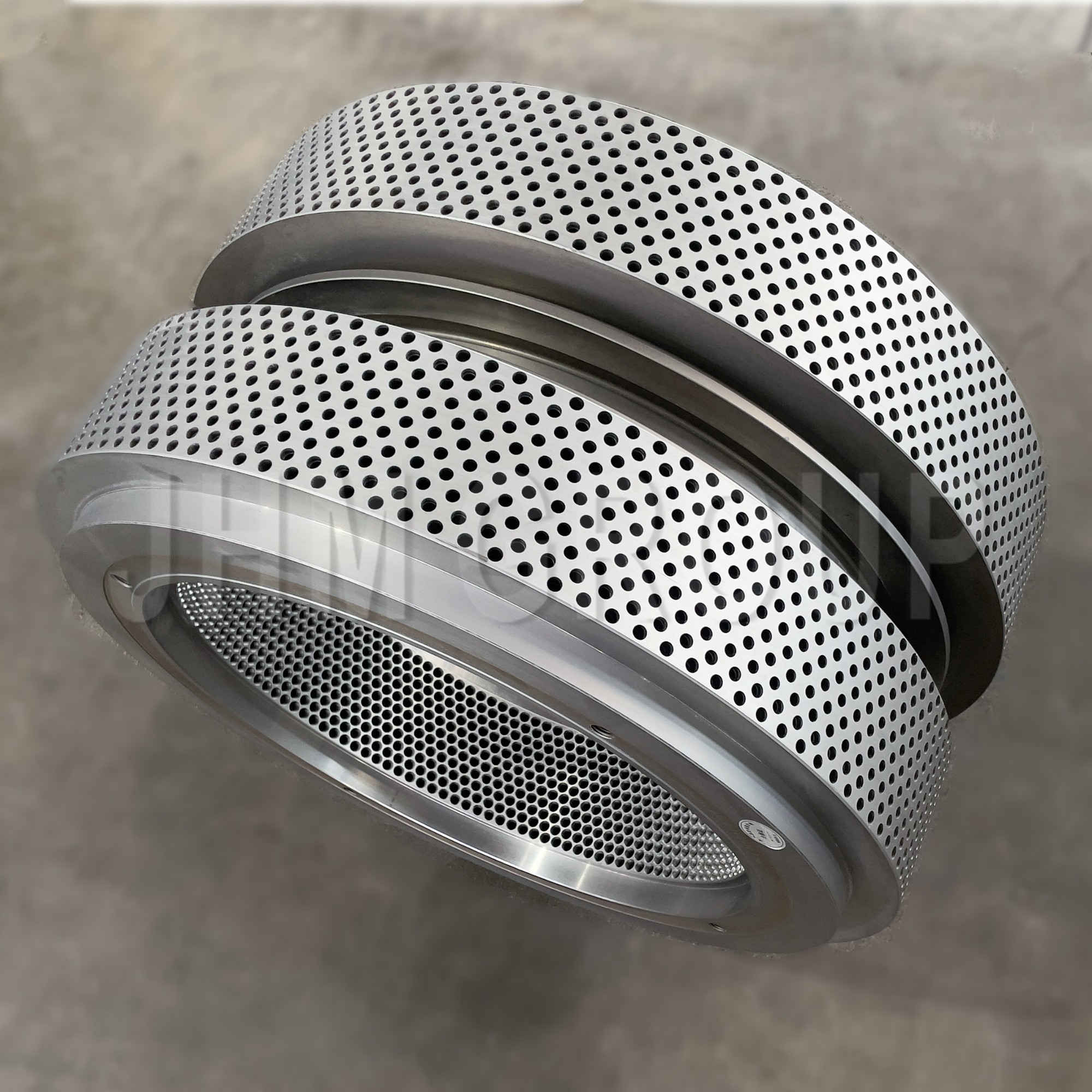

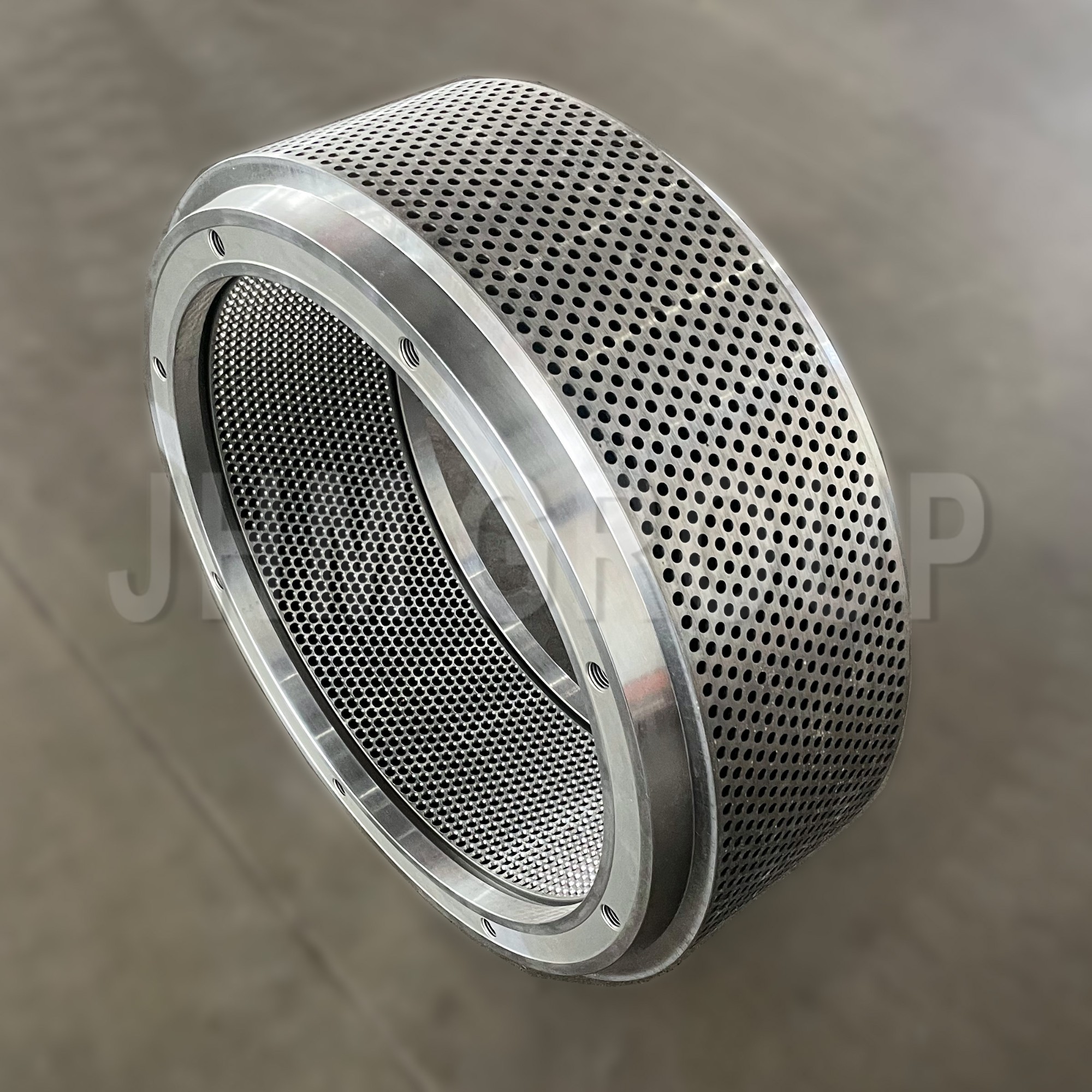

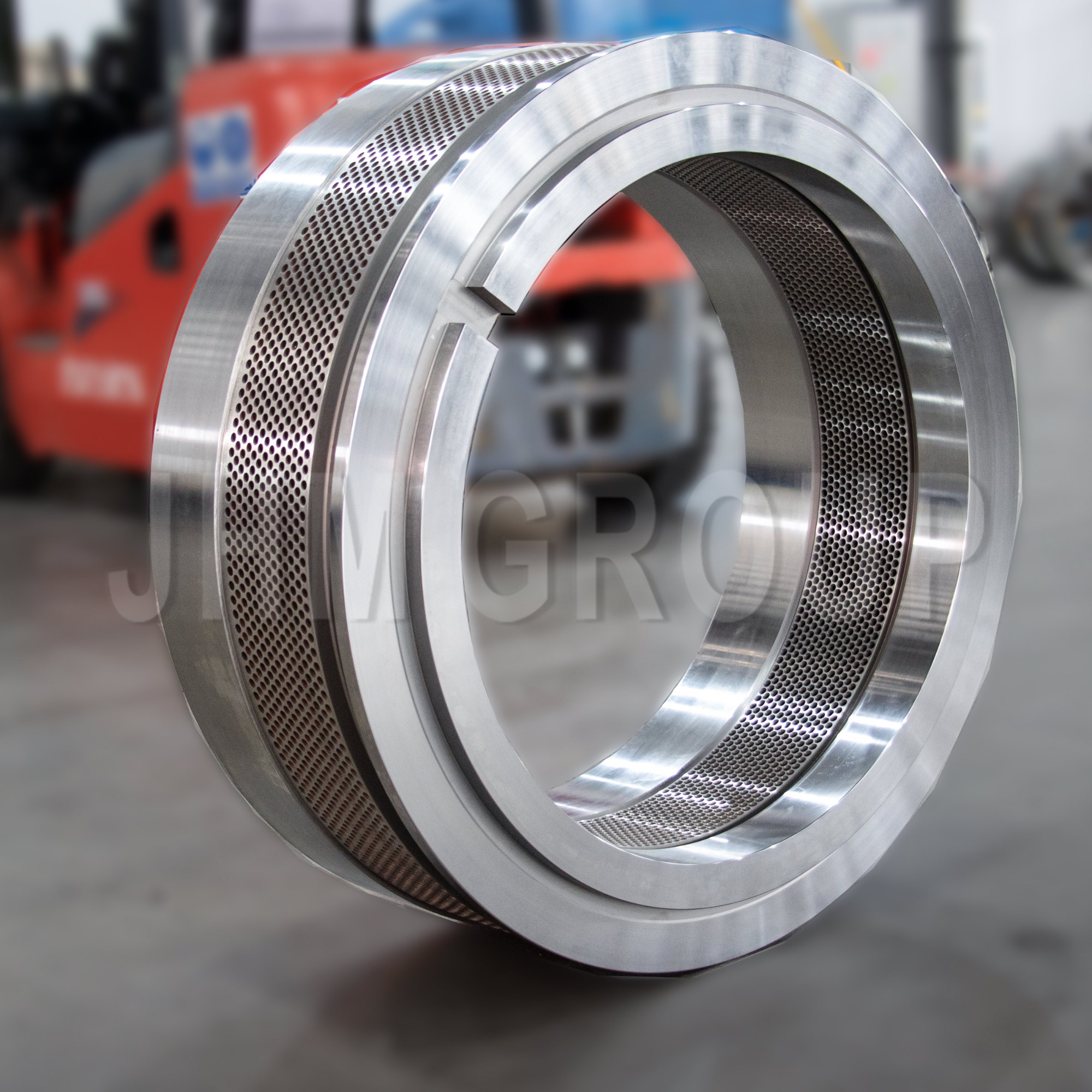

- Biomass pellet die

- 6.0-8.0mm

- 6-8

- 36-46%

- 300-1000hours

Products Description

Biomass pellet ring dies are core components of biomass fuel pelletizing equipment and are widely used to pelletize high-fiber raw materials such as sawdust, straw, rice husks, coconut shells, bamboo powder, and palm oil. Due to the high hardness and fiber content of biomass raw materials, the ring die structure requires higher strength and wear resistance.

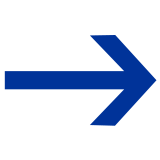

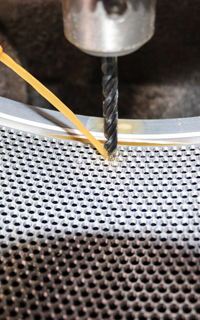

JIUHE's biomass pellet dies are made of high-strength alloy steel or stainless steel, incorporating deep-hole drilling, high-temperature quenching, and vacuum heat treatment technologies. They offer excellent wear and heat resistance, as well as long-term stable operation.

Product Parameters

|

Material |

Hardness |

Hole Diameter |

Hole Surface Roughness |

Hole Size Error |

|

X46Cr13 |

52-55 |

1.0-30mm |

0.4-0.8μm |

±0.04mm |

|

20CrMnTi |

58-62 |

3.0-30mm |

1.6-3.2μm |

±0.04mm |

Remark: Opening rate of pellet die depends on the thickness and application finally.lf the die is not thick enough, opening rate shall be decreased appropriately to avoid crack.

Product Features

·Material: X46Cr13 & alloy steel

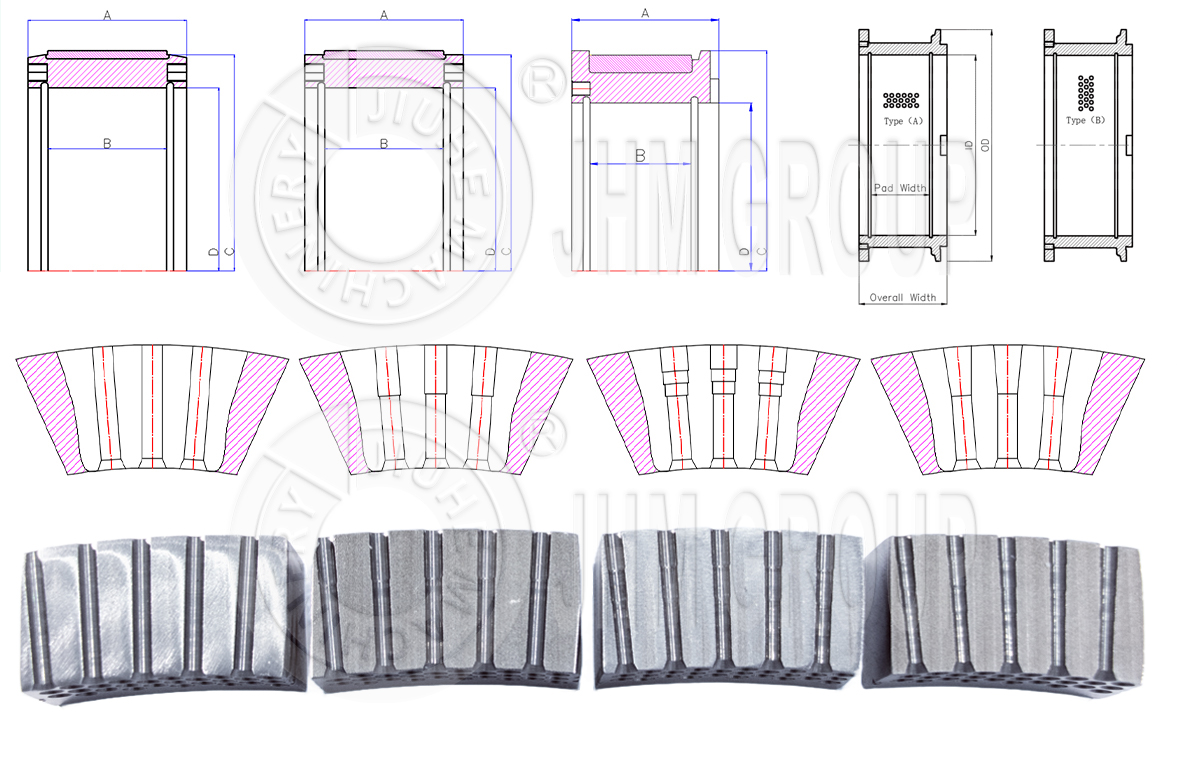

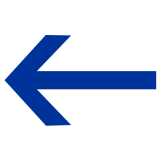

·Diversified die holes, including straight holes, stepped holes (release/compression), external tapered holes, etc., suitable for different raw material characteristics (such as cellulose, straw) and particle density requirements.

·Jiuhe biomass pellet ring molds customize the compression ratio and die hole structure according to the characteristics of different materials such as sawdust, bamboo chips, straw, palm, peanut shells, etc. to ensure the pellet forming rate and density.

·After vacuum quenching treatment, the die hole structure is stable, not easy to deform, and the service life is extended.

·Service Time: 400-1000Hours

Our die is characterized by its special distribution of holes. The relative position and pattern of our die holes improve optimum capacity of the pellet mill. The unique hole distribution of the die ensures:

1. Longer life (even wear)

2. Higher capacity with the same Die open area

3. Lower power consumption per ton of produced product

Pellet Die Type

JIUHE MACHINERY can customize the out shape and hole shape of the pellet die according to pellet type, raw material, customer demand and application. Mould shape: screw type with bevel edge,screw type with straight edge,clamp type.Hole shape: straight hole,straight hole with single relief,straight hole with multi relief,straight hole with conical relief.

Production Process

Metal Forming

Metal Forming

Lathed

Lathed

Ultrasonic testing

Ultrasonic testing

hole drilling

hole drilling

Automatic chamfering

Automatic chamfering

Vacuum quench

Vacuum quench

Inspection and Measurement

Our expert team is available to guide you by selecting the right die. In addition, we have service agency in different countries, such as Russia, Iran, Egypt, Bangladesh, India, etc,which can help solve all kinds of problems you face in time.Our engineer will also visit our client annually.

Production Application

Applicable fields: Particularly suitable for wood fiber materials (wood chips, branches, sawdust), straw, rice husks, etc., with moderate moisture content requirements (12%-15%); Can process complex structure raw materials (such as palm shells, fungus residue), but need to be pre-processed to particle size ≤ 5mm; Large-scale production scenarios such as industrial fuel pellets (high density) and feed pellets.

Tips

The core advantage of biomass pellet die lies in its high-yield, high-density pellet forming capability and the stability of large-scale production, which is particularly suitable for industrial scenarios with strict requirements on pellet quality and output.

Its vertical structure design, wear-resistant alloy material and intelligent control system further improve energy efficiency and durability, but attention should be paid to raw material pretreatment (particle size, moisture content) and regular maintenance to achieve optimal performance.

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger