- 6-8mm

- 6-8

- 36-46%

- 300-1000 hours

- 10-75days

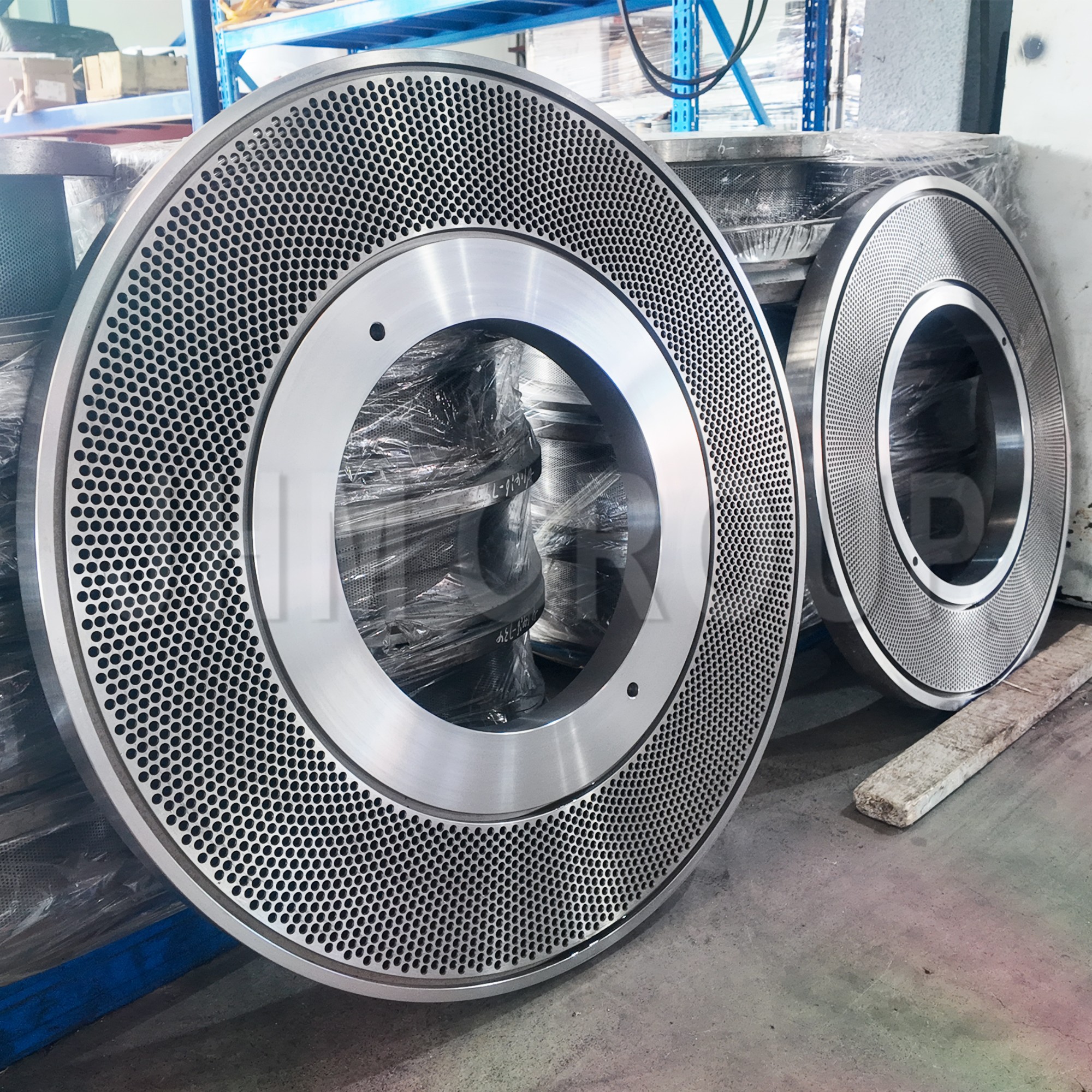

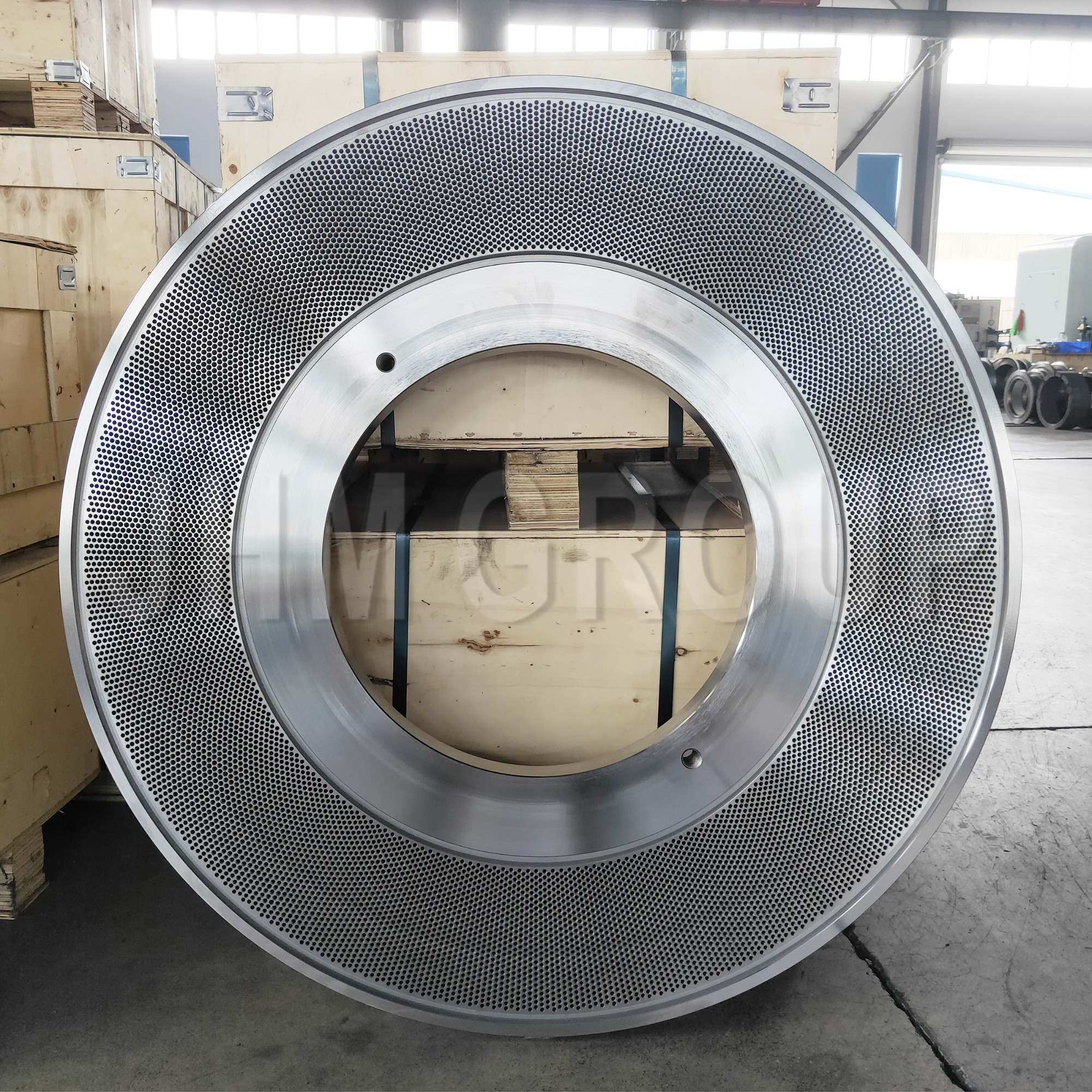

Products Description

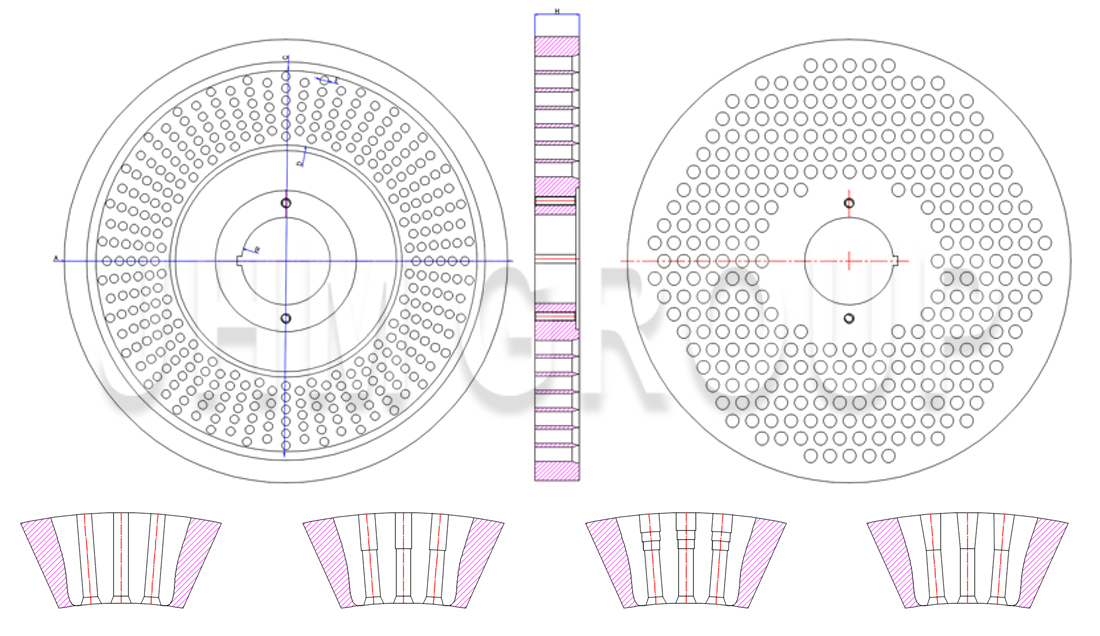

Flat die is the very heart of pelleting process, giving the final product the required shape,structure and hardness.Applicable to poultry feed, livestock feed, biomass fuel, aquatic feed and other breeding industries.

With years of development, JIUHE MACHINERY can customize all shapes of pellet die for all pellet mill brands worldwide, outer diameters ranging from 200mm to 1500mm,and hole diameters from 2.0-30mm,using only high-quality raw material and most-advanced equipment.

Products Fertures

Features Of Our Biomass Flat Dies

Biomass flat dies are ground inside in order to eliminate any deformation (guaranteed maximum deformation 0.3-1mm after heat treatment, and 0.1-0.3mm after grinder process).

1.Our biomass flat dies rapidly achieve full production because they have

-

Perfect finish of the holes

-

Vacuum heat treatment eliminating oxidation of the steel

-

New flat dies can be used directly without any prestartup

2.Long life of our flat dies is assured by

-

Construction in quality steel with high carbon and chromium content (Cr≥13)

-

Suitable hardness (HRC52-56) after heat treatment

3.Moreover

-

Our pellet mill flat dies have an extremely precise and regular perforation

-

The “honeycomb” layout of the holes is faultless

Pellet Die Type

JIUHE MACHINERY can customize the out shape and hole shape of the flat die according to pellet type, raw material, customer demand and application. Mould shape: screw type with bevel edge,screw type with straight edge,clamp type.Hole shape: straight hole,straight hole with single relief,straight hole with multi relief,straight hole with conical relief.

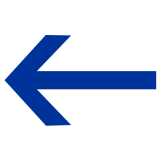

Production Process

Metal Forming

Metal Forming

Lathed

Lathed

Ultrasonic testing

Ultrasonic testing

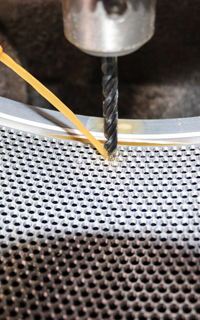

hole drilling

hole drilling

Automatic chamfering

Automatic chamfering

Vacuum quench

Vacuum quench

Inspection and Measurement

Our expert team is available to guide you by selecting the right die. In addition, we have service agency in different countries, such as Russia, Iran, Egypt, Bangladesh, India, etc,which can help solve all kinds of problems you face in time.Our engineer will also visit our client annually.

Production Application

Applicable fields : Application areas: Supports the production of a variety of biomass fuel pellets, including direct forestry raw materials (sawdust, wood chips, logging residues), wood industry by-products (wood shavings, scraps, plywood/MDF waste), agricultural waste (corn straw, rice husks, sugarcane bagasse, peanut shells, sunflower seed shells, palm kernel shells, olive branches, grapevines, etc.), recycled wood (construction waste, pallets, packaging boxes, park dead branches, shrub prunings), etc.

Tips

Feed flat dies are suitable for small and medium-sized feed mills and have the ability to process a variety of raw materials.

For medium and large feed mills that pursue high-yield and high-standard production, flat dies have more advantages in efficiency and pellet quality.

The selection of flat dies needs to be evaluated based on the characteristics of the raw materials, production scale and long-term costs.

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger