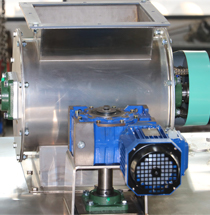

Double-slide-valve discharge mech,ensuring stable &reliable discharge.

Products Description

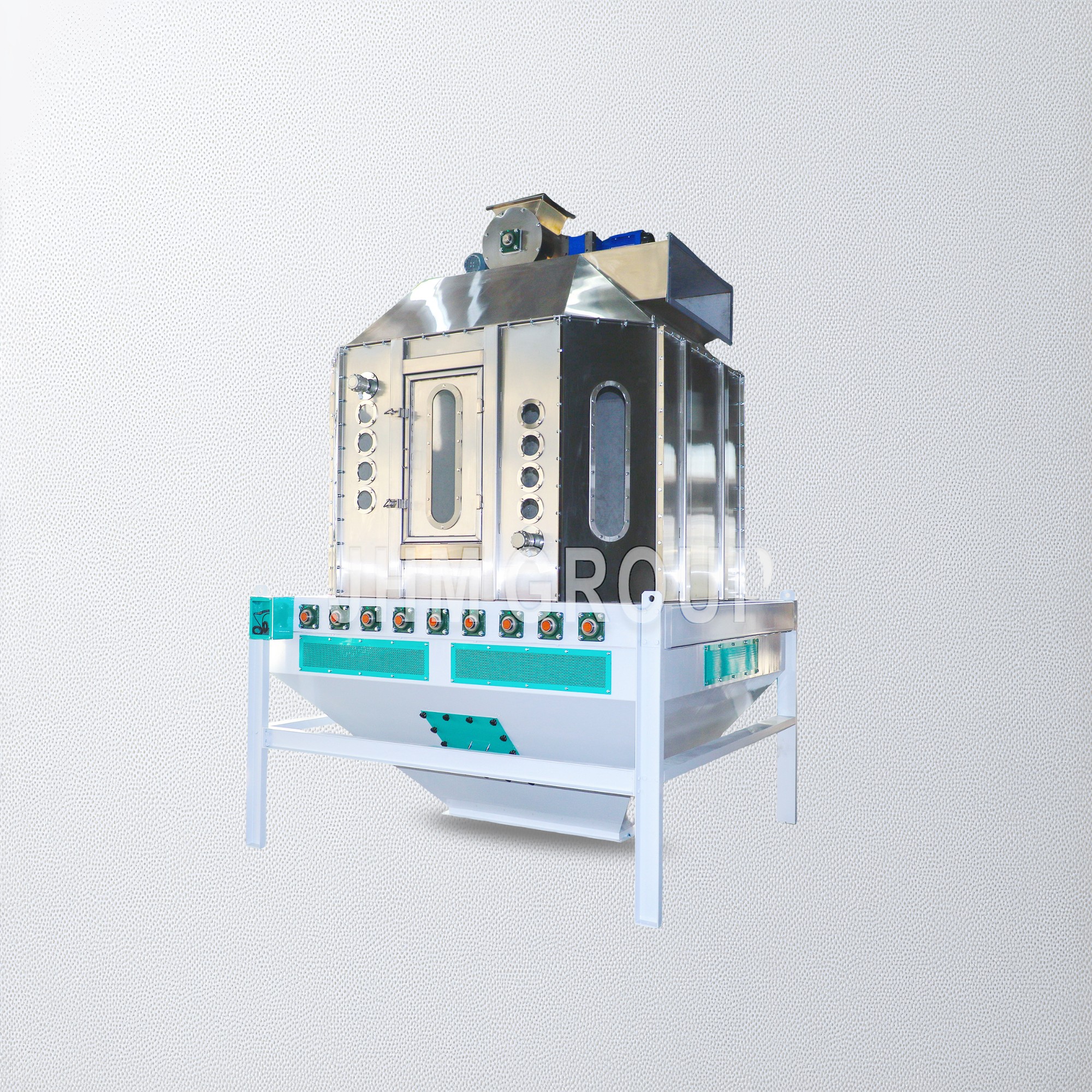

The counterflow cooler is used to cool the high-temperature pellet feed produced by the pellet mill.This counterflow cooler cools 70'℃ -90'c pellets from pellet machine to 3℃ -5℃ above room temp, achieving safe moisture (S12.5%).

Product Parameters

|

Model |

SKLN1.5 |

SKLN2.5 |

SKLN4 |

SKLN6 |

SKLN8 |

|

Power(kw) |

0.75 |

0.75 |

1.5 |

1.5 |

1.5 |

|

Capacity(t/h) |

3 |

5 |

10 |

15 |

20 |

Product Features

·The counterflow cooling principle is adopted to cool the pellets with high temperature and moisture

·All parts in contact with materials are made of stainless steel, which has a long service life Design of grinding chamber is reasonable,sieving rate is higher

·The cooling box adopts octagonal shape and the hopper adopts circular angle to reduce dead angle residue

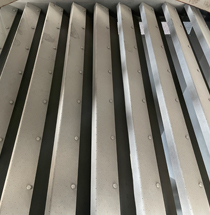

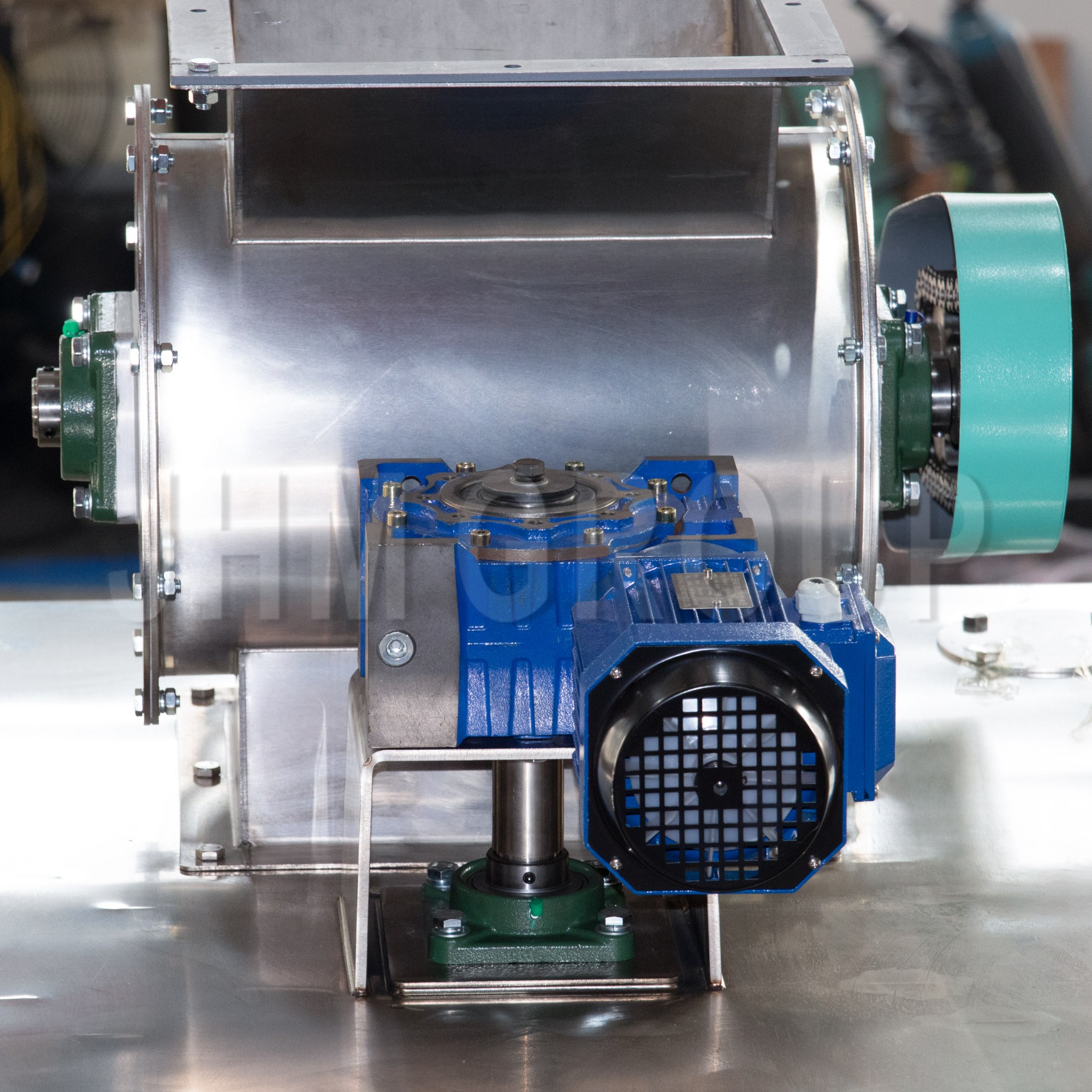

·Adopt slide valve reciprocating discharge mechanism, the movement is stable and reliable, and the residual is small

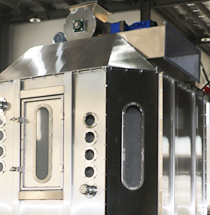

·Observation window and access door facilitate inspection and mainfenance by operatprs

More Details Of Feed Pellet Machine

With an adiustable conicabulk material mechanism,optional rotating & raking devices.

Made of 2mm stainless steel,is corrosion-resistant and durable.

Large air outlet design increasecooling speed. More efficientreducing time and labor costs.

Ring die pellet machine (also known as ring die pellet feed machine, ring die pellet feed forming machine) is a feed pelleting equipment. It is a feed processing machine that directly presses pellets from crushed materials such as corn, soybean meal, straw, grass, and rice husks.

Production Application

Application Areas: Mainly used in animal husbandry, poultry farming and aquaculture

Tips

This counterflow cooler cools 70'c-90'c pellets from pelletmill to 3'℃ -5'℃ above roomtemp, achieving safe moisture (≤12.5%).Facilitates pellet transport & storage. Modeldictatescapacity,suits diverse feeds.

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger