- Poultry Feed Pellet Die

- 2.0-5.0mm

- 9-15

- 20-40%

- 800-1200 hours

Products Description

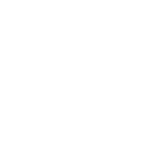

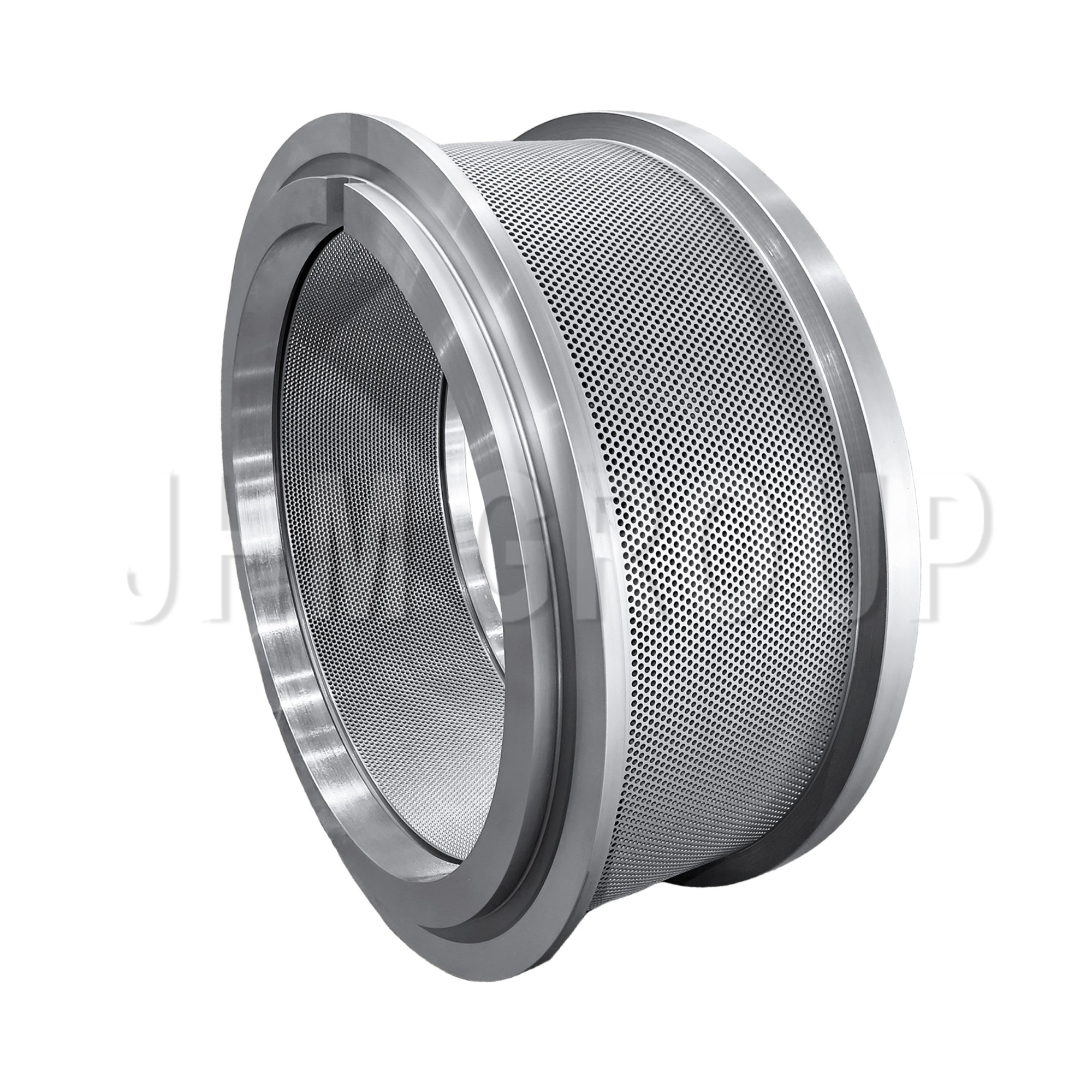

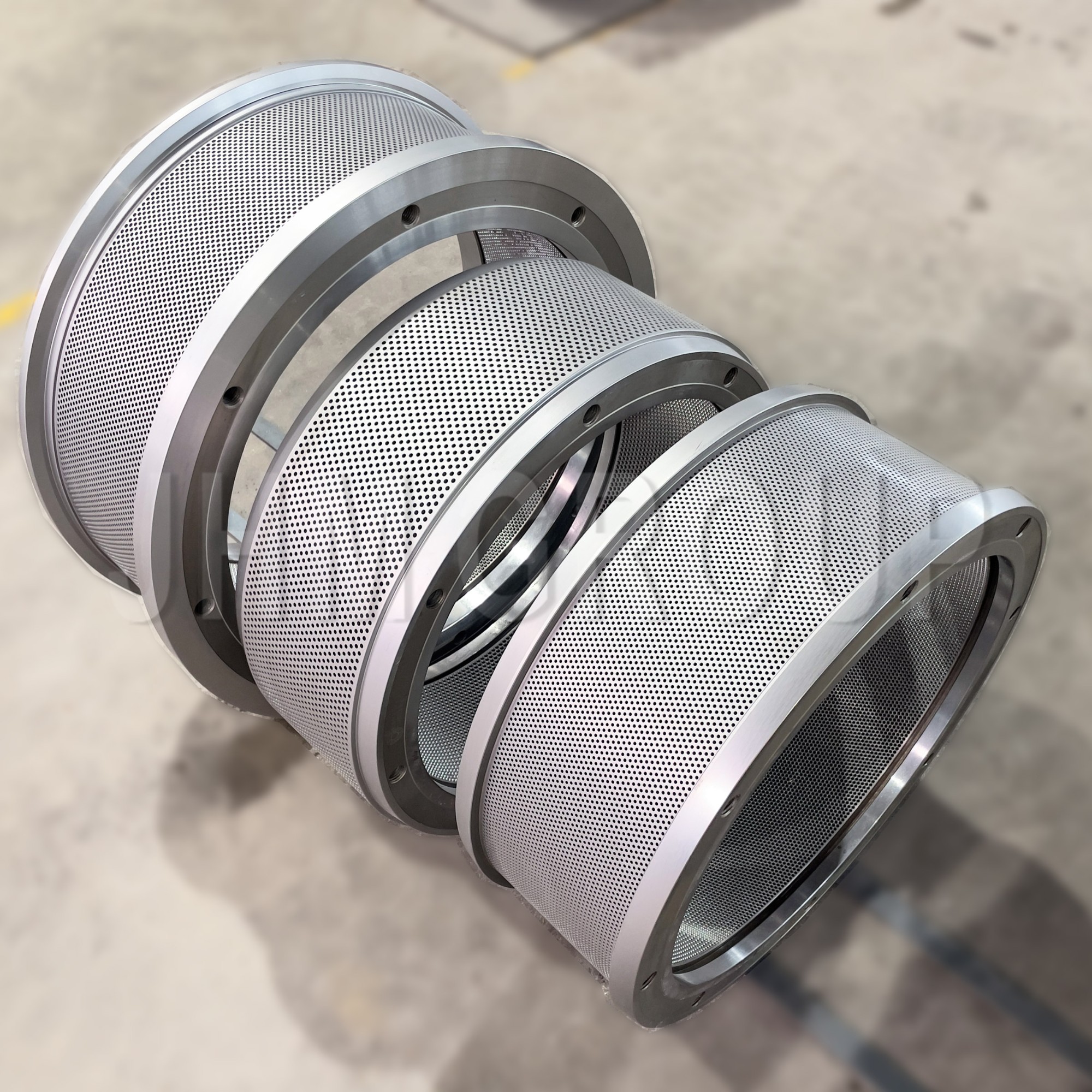

Poultry feed ring dies are essential components developed specifically for pelleting feed for chickens, ducks, geese, and other poultry. They are widely used in livestock and poultry feed production lines. Made from high-quality alloy steel or stainless steel, these ring dies utilize advanced deep-hole drilling and heat treatment processes to ensure excellent wear resistance, smooth discharge, and precise pellet formation. Whether producing meat or egg-laying poultry feed or concentrates, they deliver efficient and stable pelleting performance.

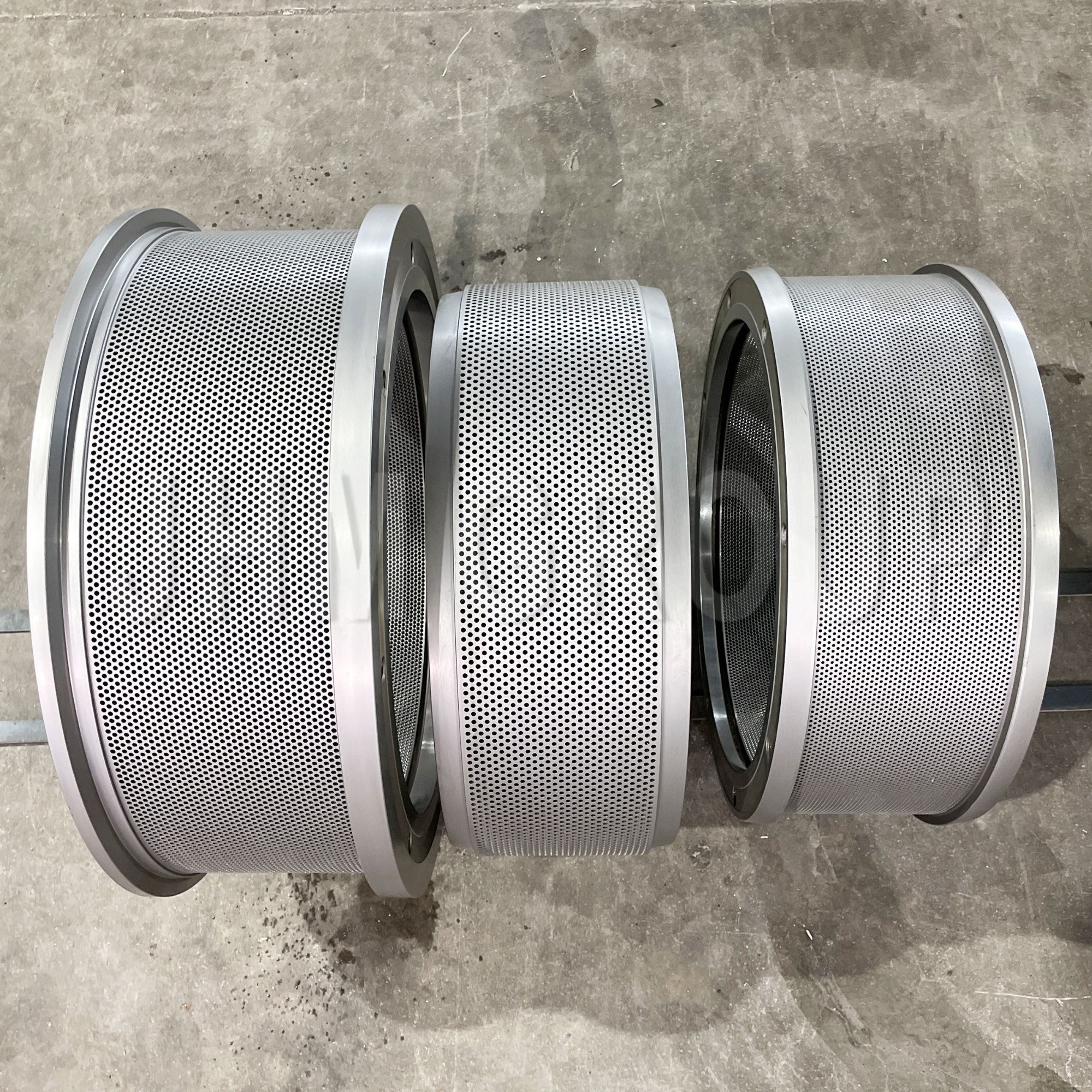

JIUHE MACHINERY can customize all shapes of pellet die for all pellet machine brands worldwide, inner diameters ranging from 200mm to 1500mm, and hole diameters from 1.0-30mm, using only high-quality raw material and most-advanced equipment.

Product Parameters

|

Material |

Hardness |

Hole Diameter |

Hole Surface Roughness |

Hole Size Error |

|

X46Cr13 |

52-55 |

1.0-30mm |

0.4-0.8μm |

±0.04mm |

|

20CrMnTi |

58-62 |

3.0-30mm |

1.6-3.2μm |

±0.04mm |

Remark: Opening rate of pellet die depends on the thickness and application finally.

lf the die is not thick enough, opening rate shall be decreased appropriately to avoid crack.

Ring die for poultry feed production. Aperture compression ratio can be customized.

Product Features

·Material: X46Cr13

·Normal Models Available or Customer Offers the Drawing

·Price as per the Model and Details

·JIUHE Machinery can customize all kinds of poultry feed pellet ring die with different hole size, based on customers' demand, or detailed drawing.

·The hardness for 46Cr13 ring die is 52-56, and difference between each part is less than 2.

·After heating(under 1050℃) and refrigeration and quenching, the ring die comes into some deformation infinitesimally, 0.3-1mm, and after being processed by grinder, the deformation can decrease to 0.05-0.15mm.

·Service Time: 800-1200Hours

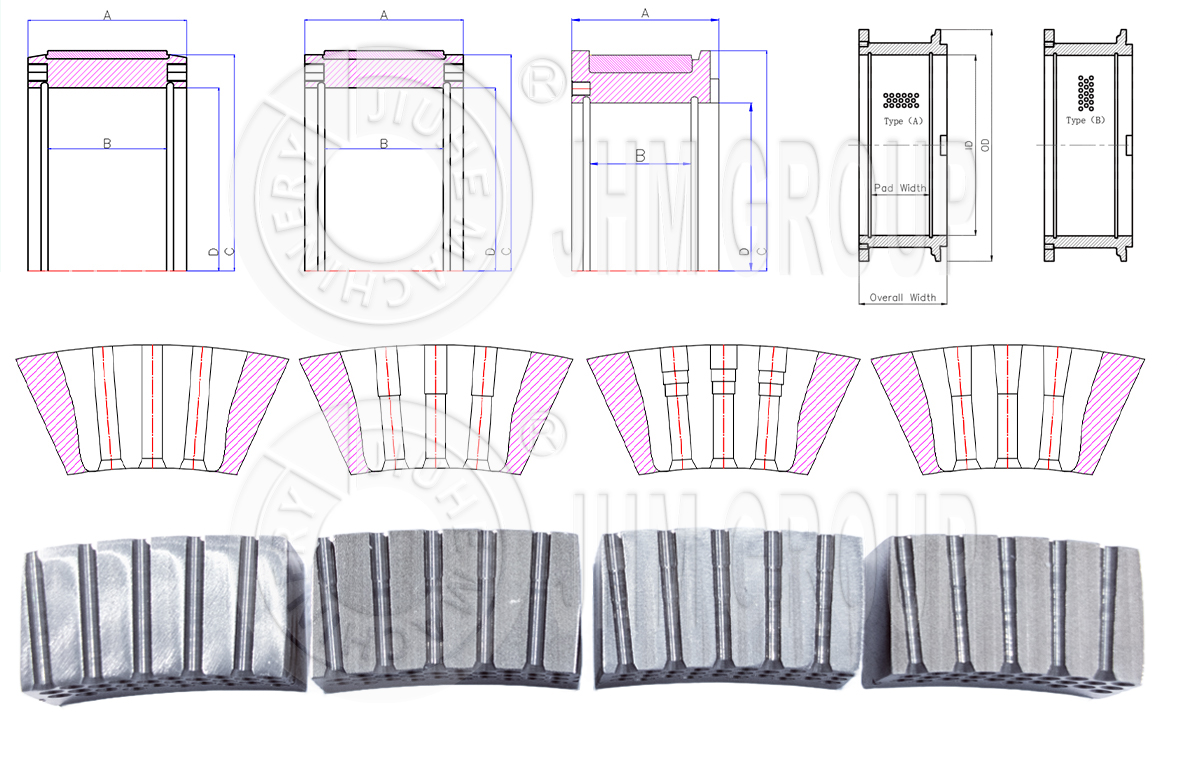

Pellet Die Type

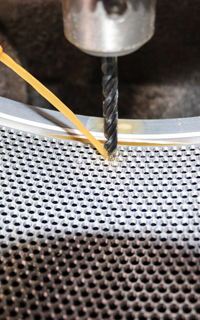

Production Process

Metal Forming

Metal Forming

Lathed

Lathed

Ultrasonic testing

Ultrasonic testing

hole drilling

hole drilling

Automatic chamfering

Automatic chamfering

Vacuum quench

Vacuum quench

Inspection and Measurement

Our expert team is available to guide you by selecting the right die. In addition, we have service agency in different countries, such as Russia, Iran, Egypt, Bangladesh, India, etc,which can help solve all kinds of problems you face in time.Our engineer will also visit our client annually.

Application Scenarios:Layer feed (improves egg production and feed conversion efficiency);Broiler feed (ensures rapid weight gain and pellet palatability);Duck and goose feed (suitable for wet feed, high-energy formulas); Supporting production lines for centralized feed mills and poultry farms.

Tips

Poultry feed pellet die optimizes the design of the discharge angle and compression structure through high-efficiency output, improves pelleting efficiency, reduces energy consumption, and achieves the unity of nutrition, efficiency and safety.

For more cases and parameters, please contact us.

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger