Ring Die Channel Cleanup

1.When ring die channels are blocked, it should be put in an iron drum, covered by lubricating oil (rather than gasoline, diesel, or any other inflammable oil), and heated. During heating, pay more attention to the oil in the iron drum, because it may catch fire at any time. After boiling, turn down the gas, and keep heating for 3 hours.

2.Install the blocked ring die on the machine immediately, mix 100-200kg pellet (diameter of the pellet should be same as ring die hole diameter. For example, 2mm die uses 2mm pellet) with 7% oil evenly. Flush the hole channel for 10-20 minutes. After all blocked channels are cleaned, we can start normal production.

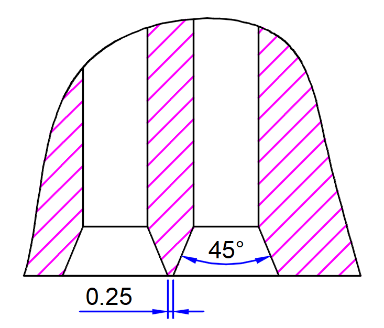

3.When ring die channels are blocked, and counter sinks are broken.It should be repaired firstly. Normal degree should be 40-45,while distance between two holes should be 0.2-0.3mm (as attached photo shows).

4.Put blocked die in an iron drum, covered by lubricating oil (rather than gasoline, diesel, or any other inflammable oil), and heated. During heating, pay more attention to the oil in the iron drum, because it may catch fire at any time. After boiling, turn down the gas, and keep heating for 3 hours. It should be kept in cooling oil for another 8 hours before take out, to guarantee the carbonation of the material which is blocked in hole channel, and help extrude more easily.

5.Install the blocked ring die on the machine, mix 100-200kg pellet (diameter of the pellet should be same as ring die hole diameter. For example, 2mm die uses 2mm pellet) with 3-5% water and 4%-5% oil evenly. Flush the hole channel for 10-20 minutes. After all blocked channels are cleaned, we can start normal production.

Ring Die Adjustment

2.After machine works stably, increase feeding speed step by step to 100%, and adjust the amount of steam. It’s quite important to guarantee the material with suitable temperature.

3.Open feeding twist dragon, decrease 80% of normal feeding speed, meanwhile, open the steam valve. The first 100-200kg material must avoid entering ring die; material whose temperature is lower than normal one must avoid entering ring die, or the hole channel will be blocked easily.

4.After machine works stably, increase feeding speed step by step to 100%, and adjust the amount of steam. It’s quite important to guarantee the material with suitable temperature.

Share:

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger