- 20CrMnTi,Gr15

- Pellet mill

- HRC58-62

- Customized

- 10-75days

Products Description

The roller shell is the core working component of equipment such as pellet mills and pellet machines. Mainly used for biofuels, animal feed, organic fertilizer pellets, etc. Roller shell used in conjunction with the ring die to squeeze the material to be pelletized into pellet feed through the die hole.

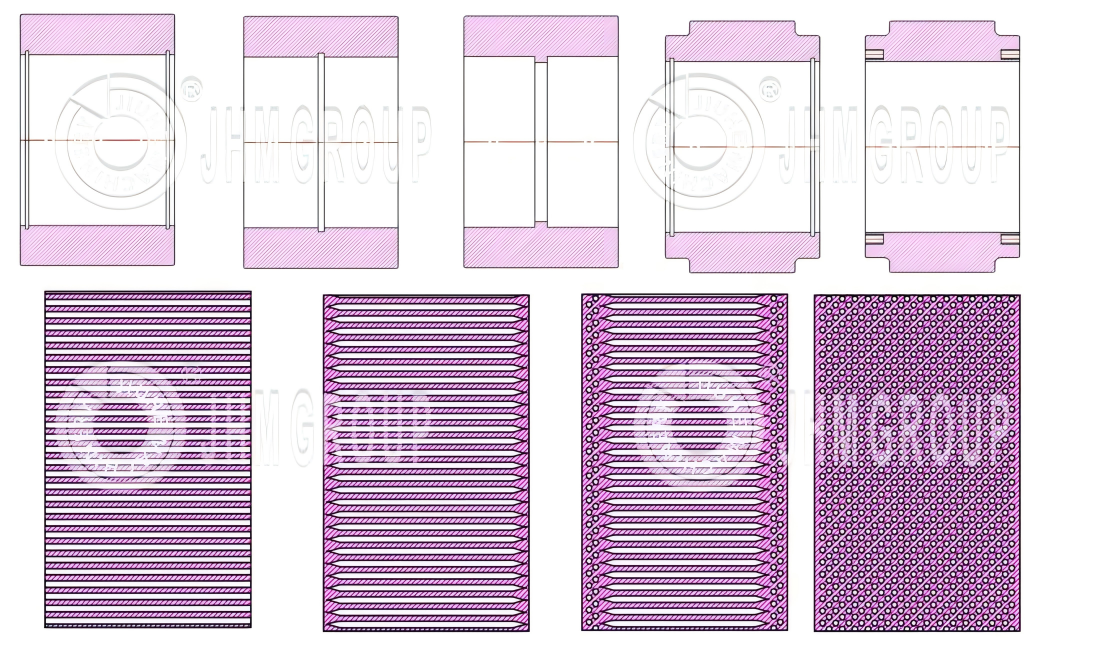

JIUHE can customize the rollers to meet your specific demands, with different surface designs, such as dimpled, straight corrugation, oblique corrugation, curved corrugation, fishbone corrugation, etc, and is always in the quality and with the service that JIUHE stands for.

Product Parameters

|

Material |

Hardness |

Hardened Depth |

|

20CrMnTi |

58-62 |

1.2-1.5mm |

|

Gr15 |

58-60 |

>5mm |

Product Features

·Material: Alloy Steel, Spring Steel, Bearing Steel

·Roller shells are manufactured by high-carbon steel 20CrMnTi, and 100Cr6 for option

·Roller shells are surface-hardened up to 58-62 HRC

·JIUHE rollers have a variety of tooth designs and can be customized according to different materials.

·Precision structure to ensure stable extrusion, deep customization capability, compatible with multiple types of pellet machines

Product Shape

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger