- Cat litter pellet die

- 1.0-3.0mm

- 1:2.5-1:7

- 12-30%

- 200-4000hours

Products Description

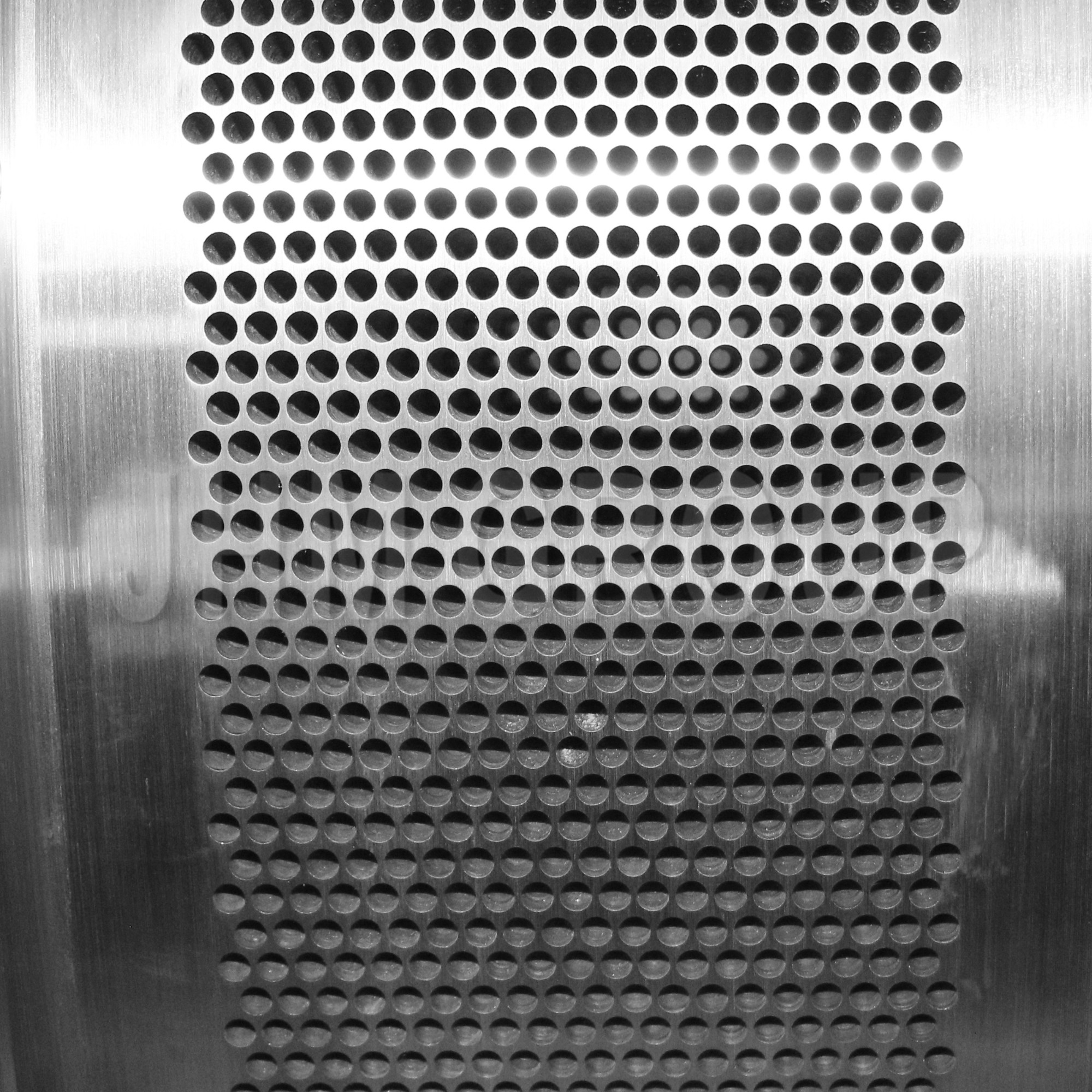

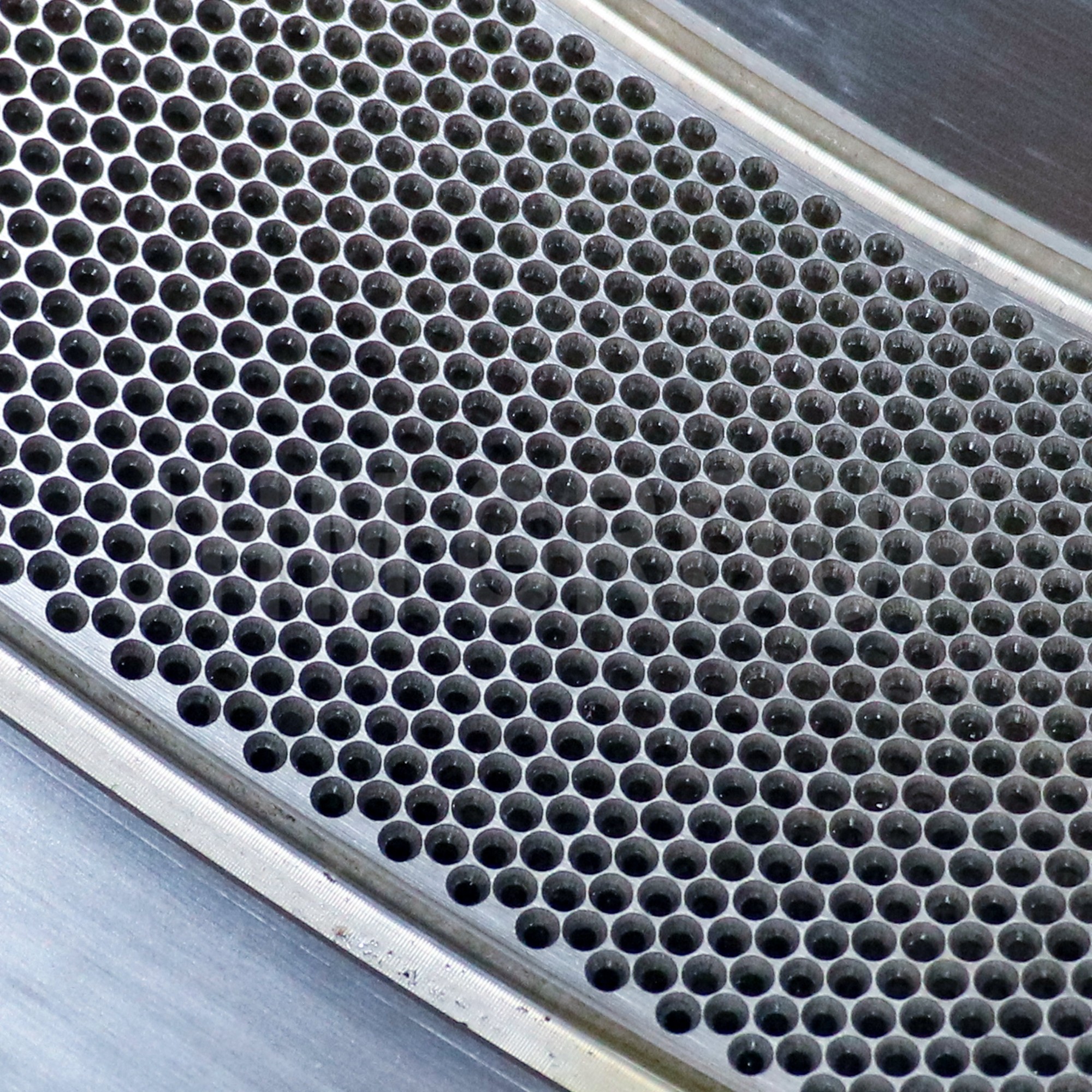

Cat litter pellet ring dies are a core component in cat litter pelletizing lines and are widely used to press and form environmentally friendly cat litters such as tofu litter, pine wood litter, corn litter, and bentonite granules. Made from highly wear-resistant alloy steel or stainless steel, and featuring precision deep-hole drilling and vacuum heat treatment, these ring dies offer excellent corrosion resistance, discharge performance, and pellet stability. They also boast a 40% water absorption rate, 95% pellet uniformity, and minimal dust production, meeting the consistent performance and appearance requirements of the environmentally friendly pet product industry.

Product Parameters

|

Material |

Hardness |

Hole Diameter |

Hole Surface Roughness |

Hole Size Error |

|

X46Cr13 |

52-55 |

1.0-30mm |

0.4-0.8μm |

±0.04mm |

|

20CrMnTi |

58-62 |

3.0-30mm |

1.6-3.2μm |

±0.04mm |

Remark: Opening rate of pellet die depends on the thickness and application finally.lf the die is not thick enough, opening rate shall be decreased appropriately to avoid crack.

Product Features

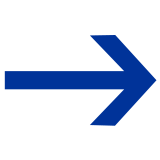

·Material: X46Cr13

·It is suitable for pressing natural raw materials such as tofu dregs, corn dregs, pine powder, starch, bentonite, etc., and supports the production of various types of cat litters.

·X46Cr13 stainless steel CNC deep hole processing is used, the wear resistance is increased by 50%, and the service life is extended to 3000 tons of output/mold.

·The cat litter pellet ring die has smooth holes and smooth discharge, which effectively avoids problems such as hole blockage, pellet breakage, and deformation, and ensures the integrity of the pellet appearance.

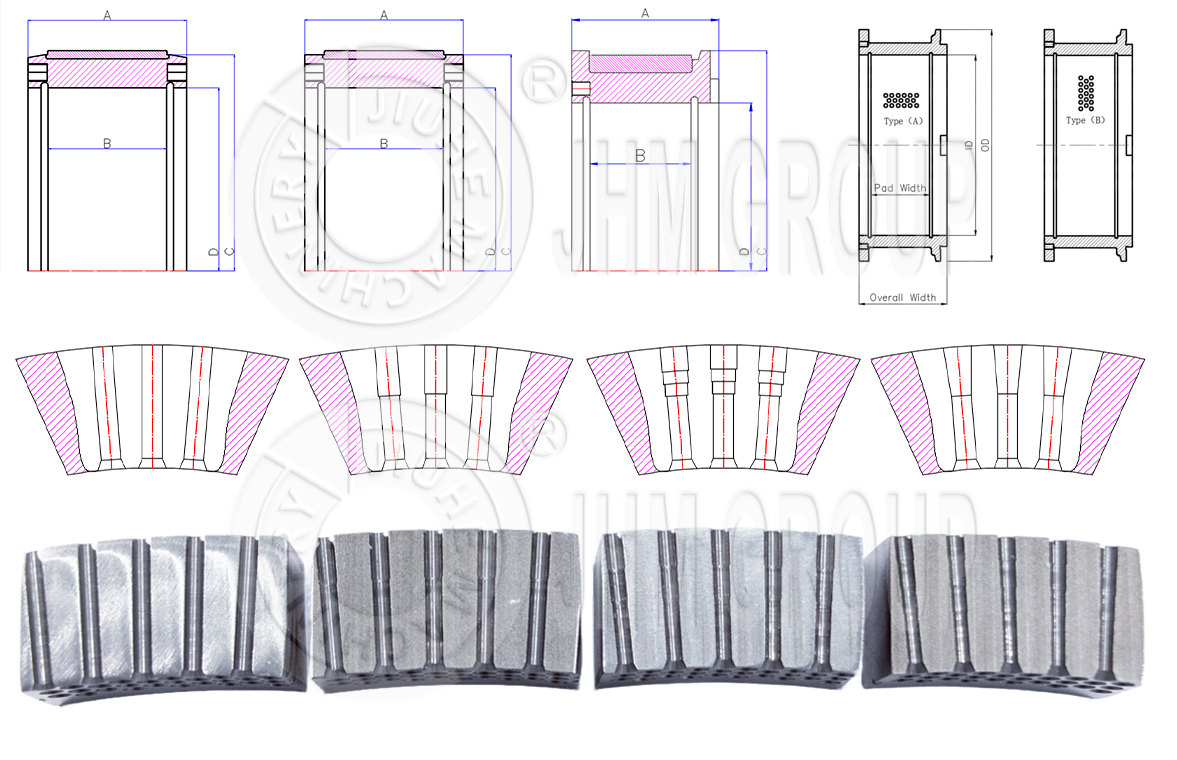

·Through different hole diameters and mold structure designs (such as straight holes and stepped holes), the shape (strips, spheres), size (diameter 1.5-6mm) and surface finish of cat litter particles can be controlled. For example, tofu cat litter needs a smooth surface to reduce dust, while bentonite cat litter needs a high-density structure to improve clumping.

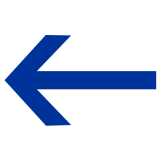

Our die is characterized by its special distribution of holes. The relative position and pattern of our die holes improve optimum capacity of the pellet mill. The unique hole distribution of the die ensures:

1. Longer life (even wear)

2. Higher capacity with the same Die open area

3. Lower power consumption per ton of produced product

Pellet Die Type

JIUHE MACHINERY can customize the out shape and hole shape of the pellet die according to pellet type, raw material, customer demand and application. Mould shape: screw type with bevel edge,screw type with straight edge,clamp type.Hole shape: straight hole,straight hole with single relief,straight hole with multi relief,straight hole with conical relief.

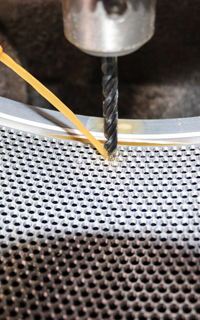

Production Process

Metal Forming

Metal Forming

Lathed

Lathed

Ultrasonic testing

Ultrasonic testing

hole drilling

hole drilling

Automatic chamfering

Automatic chamfering

Vacuum quench

Vacuum quench

Inspection and Measurement

Our expert team is available to guide you by selecting the right die. In addition, we have service agency in different countries, such as Russia, Iran, Egypt, Bangladesh, India, etc,which can help solve all kinds of problems you face in time.Our engineer will also visit our client annually.

Production Application

Application range:Tofu cat litter pellet molding;Pine wood cat litter pressing;Corn cat litter, bentonite cat litter secondary granulation;Pet products OEM production line supporting use.

Tips

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger