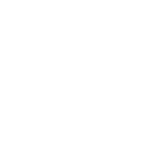

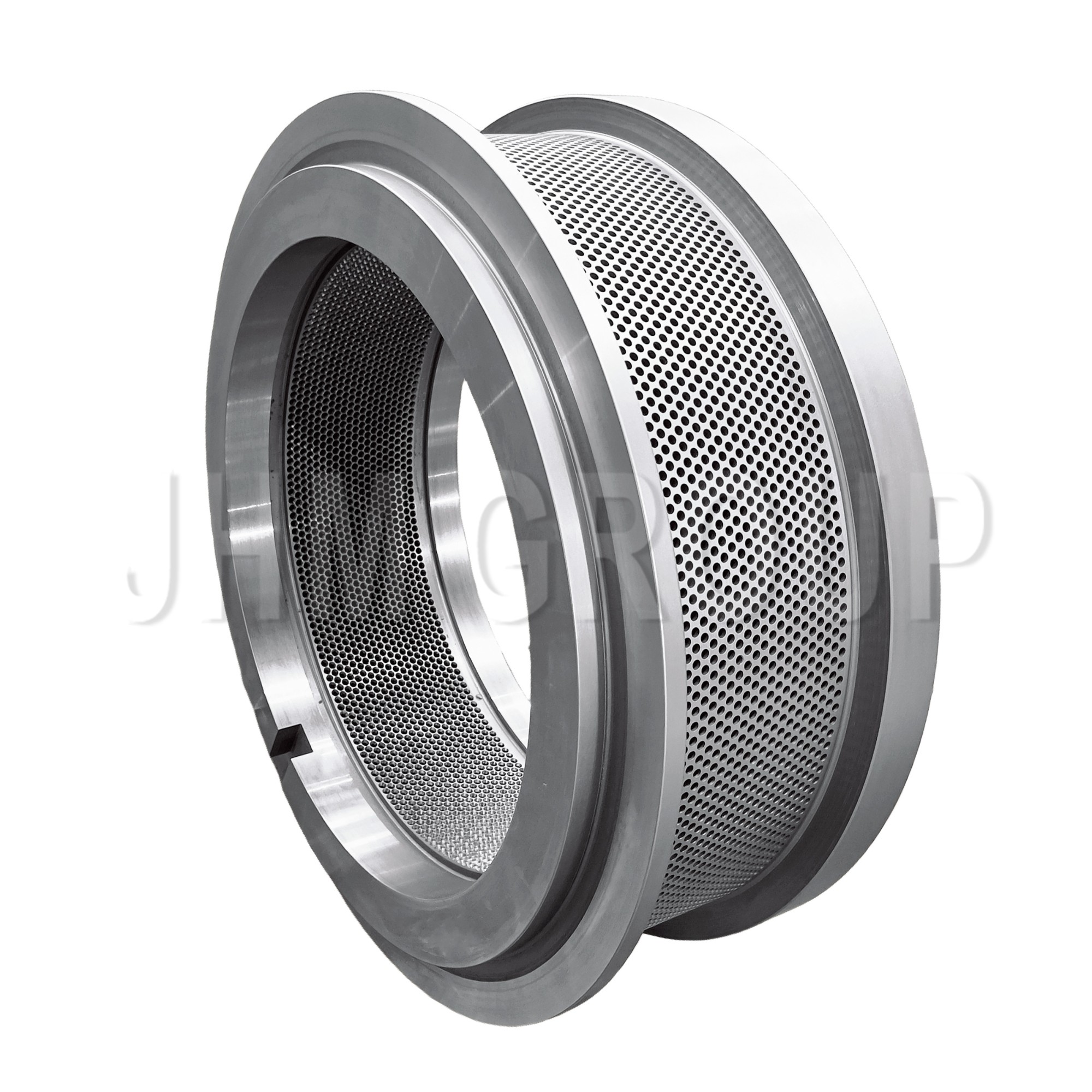

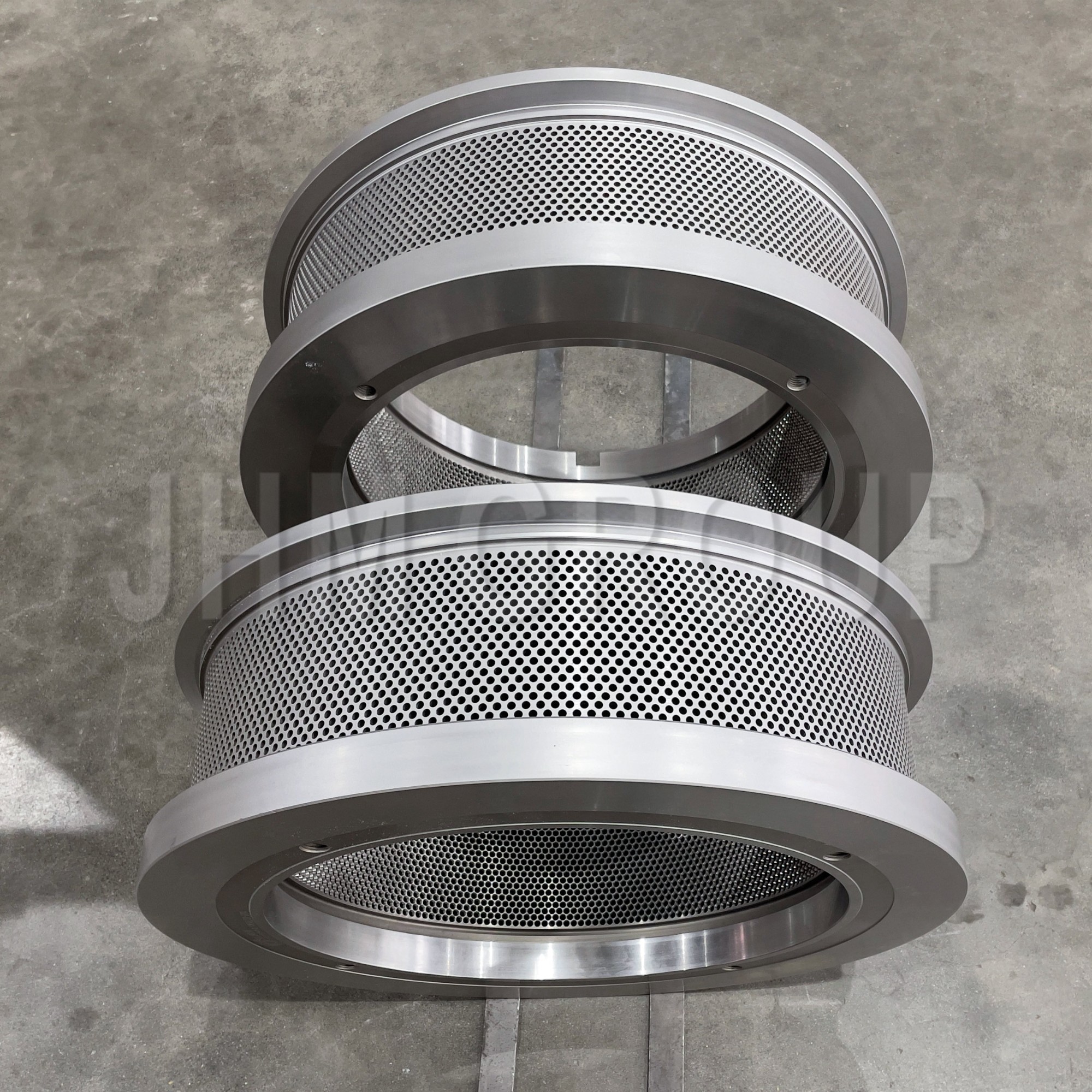

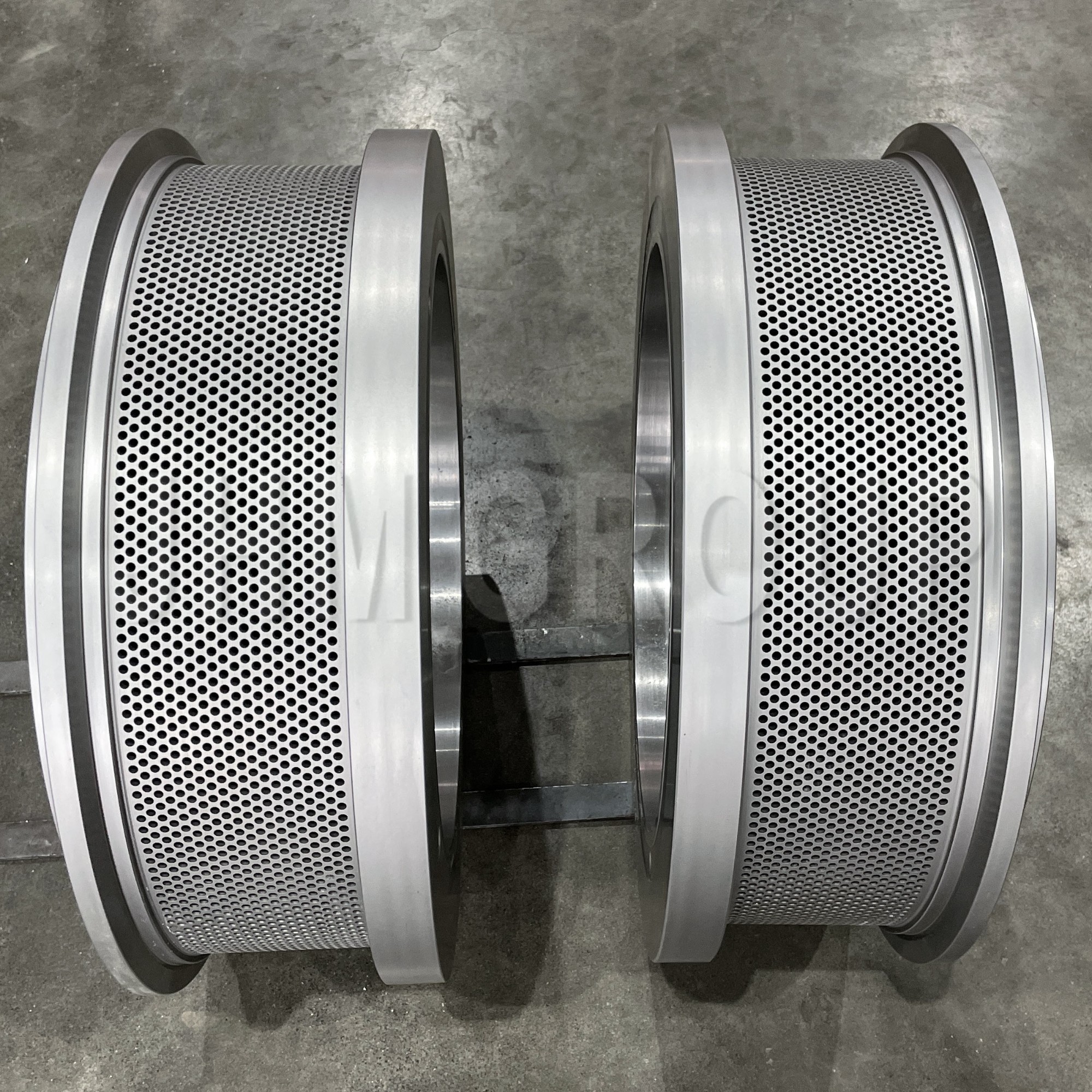

- Fertilizer feed pellet die

- 4.0-18.0mm

- 4-10

- 36-46%

- 300-1000hours

Products Description

Fertilizer pellet ring die is a key component in organic fertilizer, compound fertilizer and biofertilizer granulation equipment. It is specially used for high-pressure molding of raw materials such as animal manure, crop straw, urban sludge, compost, organic residue, etc. In view of the characteristics of fertilizer raw materials such as strong corrosion, high moisture content and easy scaling, our fertilizer feed pellet die is made of corrosion-resistant alloy steel or stainless steel, and the wear resistance is improved through deep hole drilling and vacuum heat treatment technology, and the service life can reach 300-1000 hours. High-quality ring die reduces the frequency of downtime replacement and reduces maintenance costs.

Product Parameters

|

Material |

Hardness |

Hole Diameter |

Hole Surface Roughness |

Hole Size Error |

|

X46Cr13 |

52-55 |

1.0-30mm |

0.4-0.8μm |

±0.04mm |

|

20CrMnTi |

58-62 |

3.0-30mm |

1.6-3.2μm |

±0.04mm |

Remark: Opening rate of pellet die depends on the thickness and application finally.lf the die is not thick enough, opening rate shall be decreased appropriately to avoid crack.

Product Features

·Material: X46Cr13 & alloy steel

·Our fertilizer ring molds are made of high-grade stainless and high-nickel steel (such as stainless steel or alloy steel). After carburizing/heat treatment, the surface hardness is increased (HRC ≥ 58), the wear resistance is increased by 2 to 3 times, and the replacement frequency is reduced.

·Jiuhe tailors the compression ratio and pore size distribution according to the target density, hardness, disintegration time and other requirements of fertilizer particles.

·In view of the acidic components in organic fertilizers (such as livestock and poultry manure), Jiuhe performs chrome plating or coating on the surface of the ring die in the process to enhance corrosion resistance.

·Service Time: 300-1000Hours

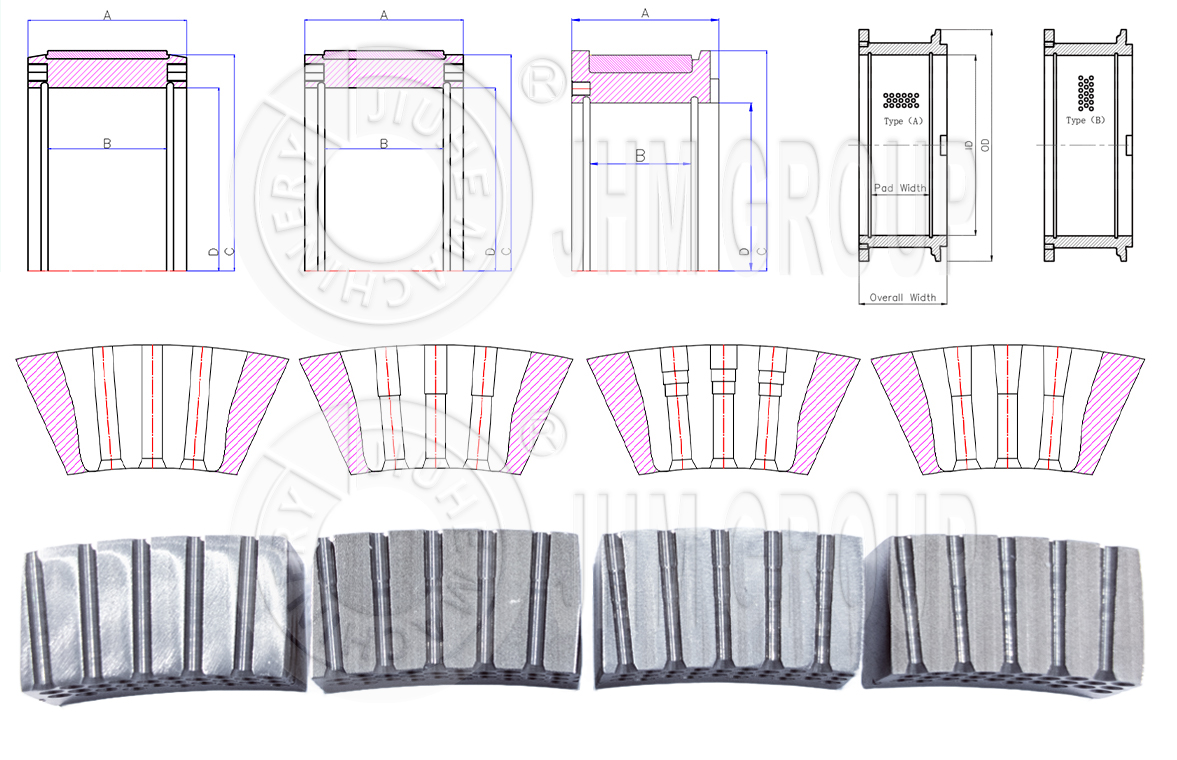

Our die is characterized by its special distribution of holes. The relative position and pattern of our die holes improve optimum capacity of the pellet mill. The unique hole distribution of the die ensures:

1. Longer life (even wear)

2. Higher capacity with the same Die open area

3. Lower power consumption per ton of produced product

Pellet Die Type

JIUHE MACHINERY can customize the out shape and hole shape of the pellet die according to pellet type, raw material, customer demand and application. Mould shape: screw type with bevel edge,screw type with straight edge,clamp type.Hole shape: straight hole,straight hole with single relief,straight hole with multi relief,straight hole with conical relief.

Production Process

Metal Forming

Metal Forming

Lathed

Lathed

Ultrasonic testing

Ultrasonic testing

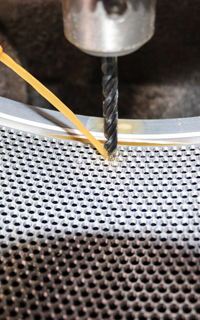

hole drilling

hole drilling

Automatic chamfering

Automatic chamfering

Vacuum quench

Vacuum quench

Inspection and Measurement

Production Application

Application Areas: Organic fertilizer and bio-organic fertilizer granulation; Agricultural waste recycling projects (straw, manure, etc.); Municipal sludge fertilizer granulation production; NPK compound fertilizer granulation processing; Specialty fertilizers such as horticultural fertilizer granules, slow-release fertilizers, and controlled-release fertilizers.

Tips

Regular maintenance: Clean residual materials to prevent clogging of die holes; Fiber raw materials need to be crushed to ≤3mm, and the moisture content should be controlled at 12%-18%.; Add steam (temperature 70-90℃) to soften the raw materials, improve plasticity and reduce ring die wear.

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger