Due to the limit of roller assmembly when installing, together with its demand of manufacturing, only little of greast is added to its inner bearing, which can’t meet the regular revolve. When using roller shell, high temperature No. 3 lithium based grease must be injected into the roller bearing, to avoid its break after turning on the machine.

As the roller assembly always works in high temperature, high-humidity, dusy environment, the lubrication of its inner bearing is extremely important. We recommend you with No. 3 lithium based grease, and add the grease every three-hour working.

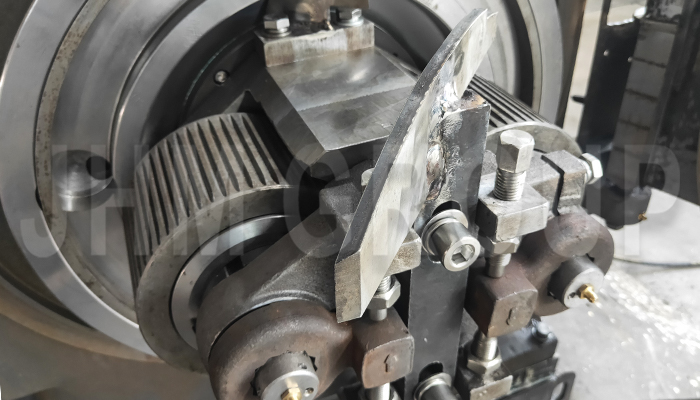

The gap in the roller shell has been adjusted by us before selling. But with more working, each part of the roller will be wore off, the gap will become larger, that’s why we need you to tighten the nuts from time to time, make the gap match its work, to extend its life.

When installing roller shell, you should check whether the work surface of roller and ring die is in suitable position. The machine can’t work under the condition that roller shell touches the ring die feed channel, or it will casue damage of the ring die and roller shell.The surface of ring die and roller shell must has a gap with distance about 0.1-0.3mm, to avoid demange on ring die and roller shell surface.

Please check frequently to avoid any wastage enter the roller channel. Wastage such as iron must be taken out as soon as possible, or it will break the wheel of the roller shell.

When pellet machine stopped during working, you should stop it as soon as possible, to avoid the machine with no-load running for long time. Otherwise, the roller shell will be out of shape, and finally affect the normal use of the pellet machine.

Share:

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger