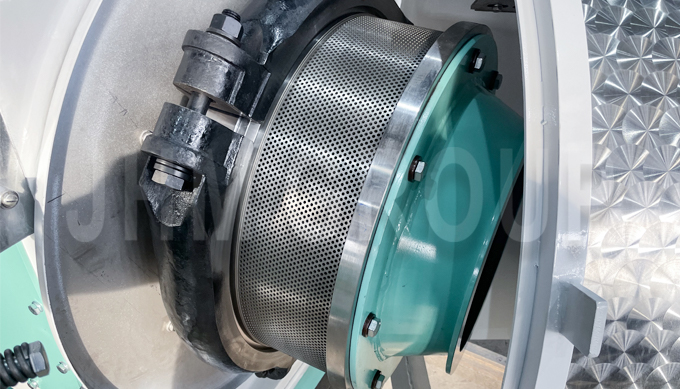

How to properly rinsing and pre-start the ring die

When rinsing the pellet die, normally there are two ways:

1. with pellet

Take the pellets just produced (the crushed size of the raw material, and the hole diameter of the hammer mill screen should not be larger than the hole channel diameter of the pellet dies to be washed). The amount of pellet depends on the size of the pellet die, such as, inner diameter is no bigger than 558mm, which needs around 50kg~100kg of pellets. The moisture content is best when the pellet is just produced and hot, so it is not necessary to add more water. Mix the pellet with 5%-10% oil (vegetable oil is best) while the pellet is hot, to rinse the hole channel of pellet die. You can also put this material into a bag sealed with a film for next pre start of pellet die.

2. with powder

Take the mixed raw material (the crushed size of the raw material, and the hole diameter of the hammer mill screen should not be larger than the hole channel diameter of the pellet dies to be washed). The amount of powder depends on the size of the pellet die, such as, inner diameter is no bigger than 558mm, which needs around 50kg~100kg of powder. Mix the powder with 4%-6% water, and 5%-10% oil (vegetable oil is best) evenly. If necessary, knead the material by hand to ensure there are no lumps because small lumps of material shall be problem for rinsing the pellet die with small hole size. Mixing thoroughly before rinsing the hole channel of pellet die is extremely important. Hard piece, such as corn, is strictly prohibited from adding into the powder.

The speed of rinsing the pellet die hole channel should be from slow to fast. Once the die is warming up, the feeding speed should be increased. If lampblack occurs during rinsing, more oil shall be added. Normally 15-30 min rinsing shall be enough. After rinsing, take 5kg raw material and mix with 10% oil, to fulfill the pellet hole channel to finish the rinse of pellet die.

Before turning on the machine, release the steam condensate, then open the pellet machine door, and turn on the feeder and conditioner, release 10-20kg raw material to finish flushing process. After that, turn off the feeder and conditioner, and close the pellet machine door.

Turn on the pellet mill and conditioner

Turn on the feeder, and open the steam value

1. 10% of normal production, 60% of normal degree

2. 20% of normal production, 70% of normal degree

3. 40% of normal production, 75% of normal degree

4. 60% of normal production, 80% of normal degree

Share:

Whatsapp

Whatsapp Facebook

Facebook Twitter

Twitter Messenger

Messenger